Cable Compatibility in Undergrounding

Undergrounding is a significant trend in the construction and maintenance of the electrical grid. New technology in cable design as well as installation improvements make it possible to reduce the total cost of the system over time. Underground infrastructure is less susceptible to damage from hurricanes, tornadoes, wildfires, woodpeckers, tsunamis, vandalism, terrorism, and so on. Industry leaders are making intentional efforts to underground.

A key to underground installations is cable longevity. Improvements in cable design increase the lifespan of the installation. When cable is pulled into duct, two other important factors affecting cable longevity involve cable lubricants. Lubricants reduce friction as the heavy, stiff wires or cables are pulled long distances into buried conduit. Because these cable systems are expensive, and because 90% of cable damage reportedly occurs during installation—typically due to the use of an insufficient quantity or inadequate quality of lubricant—a specialty, high-performance lubricant is required.

But in conduit there is a secondary concern. After the cable is successfully pulled, the lubricant or its dried residue remains in contact with the cable sheath for decades. Thus, compatibility between the cable and the lubricant is essential. Incompatible lubricants damage cable jackets and can shorten their life expectancy by years, even decades in extreme cases. This is a fundamentally important consideration in undergrounding, the whole point of which is to ensure system resiliency and longevity. Engineers and designers cannot allow one of the least expensive components in the installation—the lubricant—to threaten the entire economic rationalization of the project.

| Related Content: Coefficient of Friction in Cable Pulling — Part 1 |

Wait … What?

Many engineers expect that this is a problem solved long ago. However, neither the cable jacket nor cable lubricant industries are static. Jacket design is ever-evolving, and new lubricant formulations are continually introduced. Cable jackets vary by manufacturer, even within a general category (e.g., polyethylene). Cable lubricant manufacturers have unique, often proprietary formulations based on completely different chemistries. It is the rule rather than the exception that a given lubricant is suitable for one type of cable, but less so for another.

What’s to be done? Don’t all manufacturers—of cables and lubricants alike—regularly test for compatibility? The truth is, some more than others. In all things, it is buyer beware.

Due Diligence

Preventing a pulling compound from ruining your cable is a two-step process. One: Work with reputable cable and lubricant manufacturers to ensure materials are compatible. Two: Specify a compatible lubricant to prevent the choice from being left up to installers who may have no inkling of the issue.

How is Compatibility Tested?

Various methods have been used to test the compatibility of cable lubricants with jacket materials. Typically, the wire or cable jacket material is aged in the lubricant and the physical properties (tensile and elongation) are compared to a control. For polyethylene cable, a version of the Environmental Stress Crack Resistance (ESCR) test may be run. For electrical cables, dielectric breakdown or volume resistivity may also be tested after aging.

A Standard is Created

In 1996, Polywater® was instrumental in the development of the IEEE 1210 “Standard Tests for Determining Compatibility of Cable Lubricants with Wire and Cable.” It was created at the request of both cable manufacturers and end-users. At that time, increasing cable performance expectations coupled with the longevity of cable in conduit systems put a spotlight on the important role cable sheaths and coverings play in cable protection.

Potential interaction of lubricants with cable was a major concern, and for good reason. History showed that:

-

- Certain wax emulsion lubricants negatively affect semi-conducting jackets.

- Some soaps and waxes can “stress crack” polyethylene jackets.

- Petroleum greases and oils wreak havoc with many cable jacket materials.

IEEE 1210 provides a basis for evaluation of a specific lubricant’s compatibility with a specific cable jacket. The second revision of this standard was approved in 2023. This revision update was developed in cooperation with Canadian Standards Association (CSA). To better understand the 1210 standard, consider the physical test procedures and what they show about compatibility.

| Related Content: Hawaiian Electrical Company (HECO) and the Pearl Harbor Cable Pull |

Physical Testing

The primary function of medium and high-voltage cable jackets is physical protection. Jacket physical properties (tensile and elongation) are a primary focus in 1210. In this testing, there is a 30-day aging test compared to a water-aged control and a shorter, high-temperature test compared to a water-aged control and a non-aged control. The high-temperature test condition is jacket-specific and based on NEMA/ICEA time and temperature requirements for aging of the jacket material and polymer group.

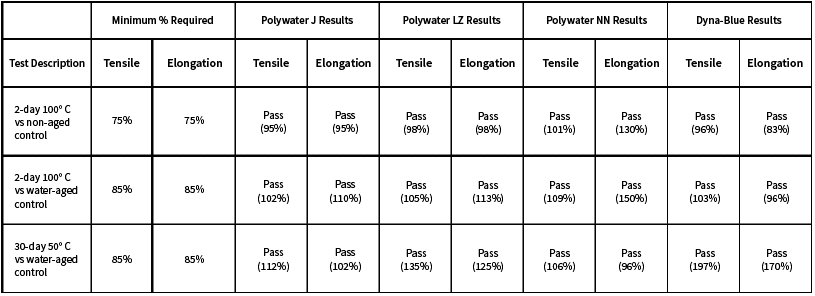

Polywater lubricants are all extensively tested to this standard. Below are results from this testing on LLDPE, a common cable jacket material. Note that the NEMA/ICEA aging test for polyethylene (PE) jackets is 2 days at 100°C, and the test is modified to include lubricant immersion of the aged sample. Percent retention requirements are listed in the chart below.

Each test specimen yields a tensile and elongation result. These values are averaged over three tests and compared to a control as noted. Results here are presented as a comparison to a control. A full test report includes the tensile force at break as well as the percent elongation. Values for each of the trials are typically shared.

Table 1: Different Lubricants with LLDPE Cable Jacket

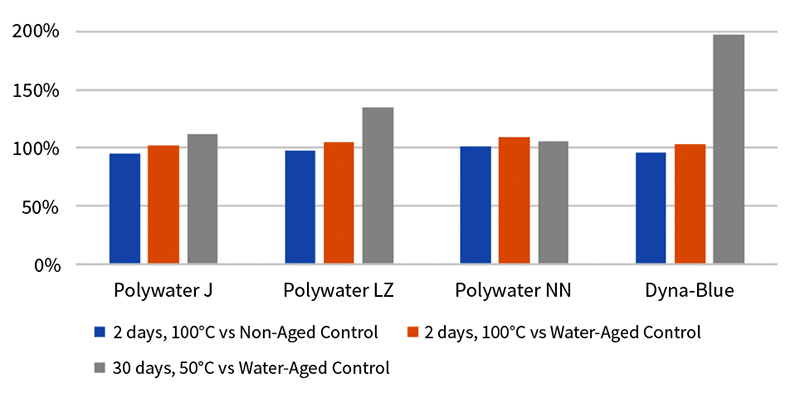

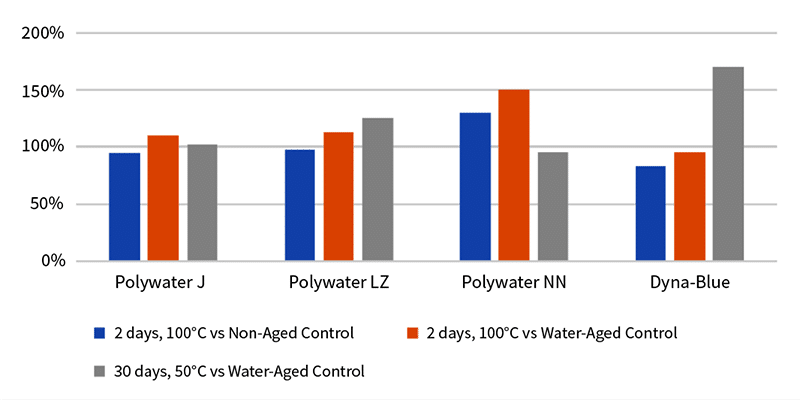

Data can also be visualized as a bar graph:

Graph 1: LLDPE Cable Jacket with Various Lubricants Comparing Tensile Values to Control

Graph 2: LLDPE Cable Jacket with Various Lubricants Comparing Elongation Values to Control

Polywater lubricants show good compatibility with LLDPE. Each lubricant must be individually tested, as results will differ depending on the chemistry of the lubricant.

| Related Content: Solution Story: The Lubricant Difference: Matching Product to Project |

Different Jackets

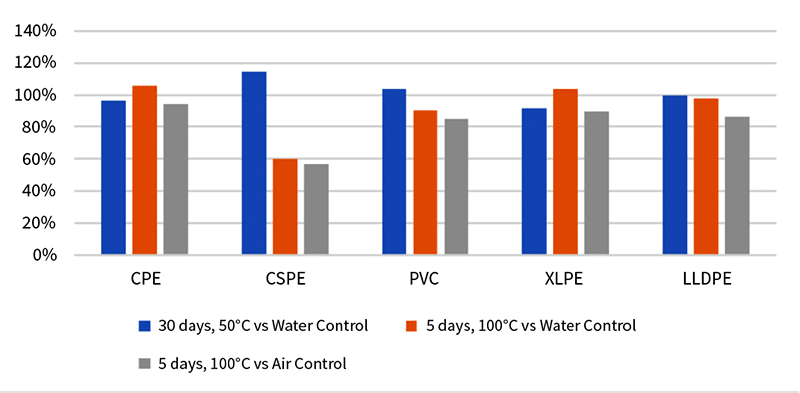

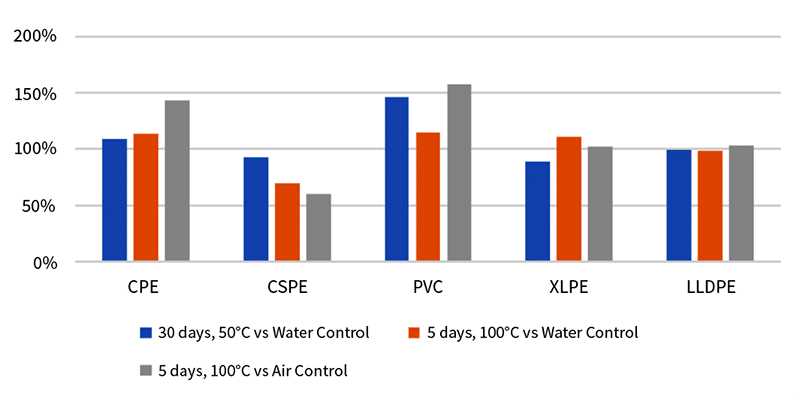

As might be expected, the same lubricant will act differently on different jackets. Below, the results from testing one lubricant with different cable jacket types are graphed.

Graph 3: Various Cable Jacket Compounds Aged in Lubricant – Tensile Strength Compared to Control

Graph 4: Cable Jacket Compounds Aged in Lubricant – Elongation Percent Compared to Control

This lubricant shows good compatibility with most cable jacket types. However, there is some incompatibility with CSPE blend tested at higher temperatures. This cable lubricant would not be suitable for use with cables utilizing this CSPE covering.

Jacket Failure

Incompatibility between lubricant and cable jacket is usually seen as loss of tensile strength or elongation in the material. This is often visually apparent as pitting or other surface damage. Sometimes represented by a softening or even excess flexibility. On rare occasions, lubricant can completely disintegrate jacket materials.

As shown in Photo 1, the low smoke, polyolefin LSZH (Low Smoke Zero Halogen) blend was aged in a wax-based lubricant and softened to the point that it fell apart even before testing.

Photo 1

As shown in Photo 2, a different low smoke, polyolefin blend, appears to literally melt when a grease is used for cable installation.

Photo 2

Wax and petroleum-based cable lubricants are not suitable for this jacket type. While these lubricants may be effective at lowering friction, they should not be used. Always consider compatibility when making a cable lubricant choice.

Cable Jacket Polymers

Within each polymer type or group (such as LLDPE or PVC) there are many individual blends. The polymer blend developed for each cable jacket is chosen for both performance and processing. Performance considerations include tensile strength, impact and puncture resistance, flexibility, and fire resistance. Processing characteristics may include ease of extrusion, melt flow, and shearing characteristics. Many cable manufacturers utilize multiple blends depending on cable style based on end use and performance expectations. The bottom line is that each cable sheath is unique. For some material groups, extensive testing may be required.

We obtained dozens of LSZH polyolefin blends for a lubricant compatibility study. Because low smoke jackets have shown incompatibility with some water-based wire and cable lubricants, Polywater has tested this polymer group extensively.

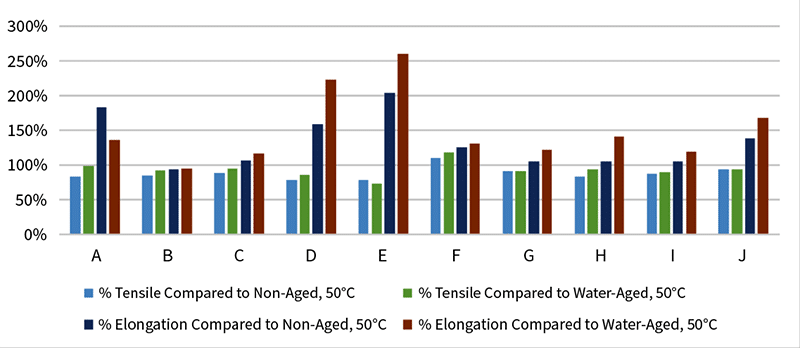

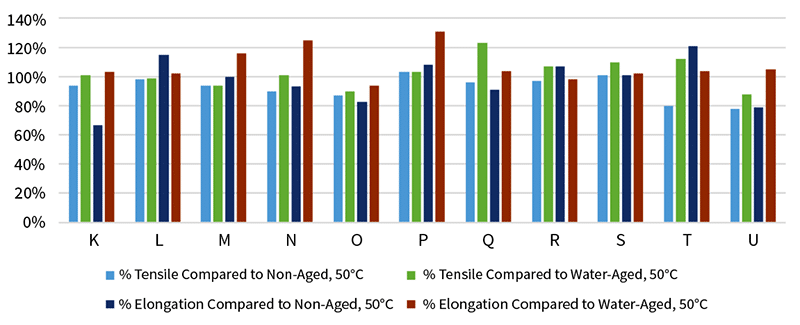

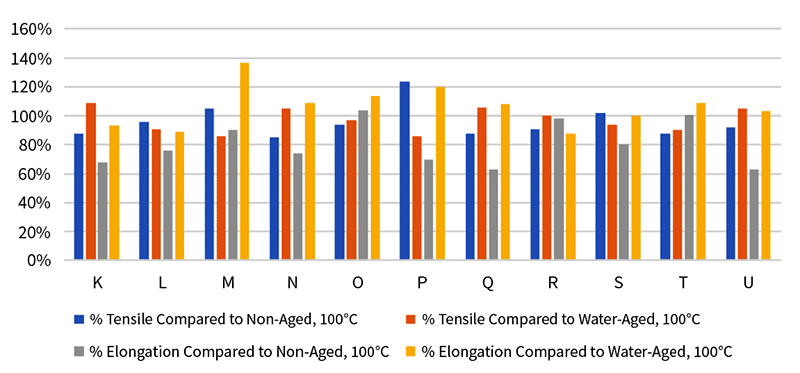

Data in the following graphs 5-8 show that each blend of LSZH polyolefin is unique. Two different lubricants tested with these blends show dramatically different results.

Graph 5: 10 Blends LSZH Aged in Lubricant A Tensile and Elongation Aged at 50°C, Compared to Control

At 100°C, cable jacket material is exposed to boiling water or–in the case of water-based lubricants–boiling lubricant. If there is incompatibility between the jacket and lubricant, it can usually be discovered in high-temperature testing.

Graph 6: 10 Blends LSZH Aged in Lubricant A Tensile and Elongation Aged at 100°C, Compared to Control

For Lubricant A, some blends of the LSZH material are compatible and others are not.

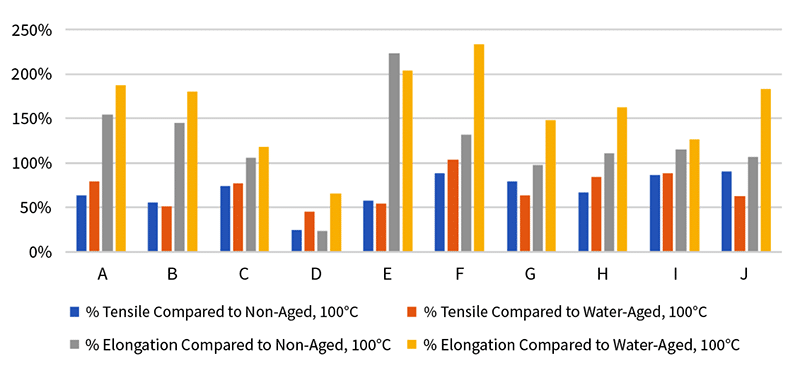

Test results for Lubricant B are shown below. Here the test results show good consistency from one polymer blend to the next.

Graph 7: 11 Blends LSZH Aged in Lubricant B Tensile and Elongation Aged at 50°C, Compared to Control

Graph 8: 11 Blends LSZH Aged in Lubricant B Tensile and Elongation Aged at 100°C, Compared to Control

Even at high-temperature testing, Lubricant B is compatible with all the jackets tested. This is not a surprise. Lubricant B is Polywater LZ and was specially developed for compatibility and performance on LSZH jacket material.

| Related Content: Total Cost of Ownership: Tools for Your Future |

Conclusion

The utility of IEEE 1210 and testing for compatibility in general is obvious. The standard provides a way to evaluate any lubricant’s interaction with a cable jacket. However, engineers should be wary of blanket statements. A simple, stand-alone claim that a lubricant has been tested and passed IEEE 1210 is essentially meaningless. It is only meaningful if it passed a test with the specific cable to be used. There is no universal 1210 test. Every test must be specific to lubricant and cable.

Other Considerations

IEEE 1210 does not ensure lubricant performance. Water passes the 1210 but is not a good pulling lubricant. While compatibility is critical, it’s equally important that a lubricant is functional and efficient. A few key properties in a high-performance, specification-grade pulling lubricant include:

-

- Coefficient of Friction — (How slippery is the lubricant? Always specific to jacket type and conduit type.)

- Coefficient of Friction “Dry” — (Is the lubricant effective for long pulls? Can cable be later adjusted?)

- Amount and Nature of Residue — (Does residue “glue” in cable over time or block conduits?)

- Residue Combustibility — (Does lube residue affect flame propagation character of fire-retardant cables?)

- Coating and Cling Character in Application — (Will lubricant coat the jacket? Does it stay on for long pulls?)

- Chemical Stability — (What are the effects of cold and/or warm storage?)

- Environmental — (Is the lubricant toxic, a hazardous waste, etc.?)

| Find the Industrial Lubricant for Your Needs |

Summary

The chemistry of lubricants and cable jackets is diverse and ever changing. This provides the potential for adverse chemical interactions that can damage cable and defeat the purpose of undergrounding utility infrastructure for system resiliency. For confidence that cable longevity is maximized, engineers should work with lubricant manufacturers who routinely test for compatibility, work closely with cable manufacturers on new product introductions, and can provide results on demand for the specific cables and lubricants you use.

Over the years, Polywater has performed hundreds of IEEE 1210 compatibility tests on untold combinations of lubricant and cable. We utilize the tests to develop new lubricant products, assist cable manufacturers in their development of new cable jackets, and to support end users in their due diligence and specification of compatible cable lubricants.