The Lubricant Difference: Matching Product to Project

Polywater® NN lowers tension in a complex and critical cable installation

Minimize Tension on High Voltage Cable

In this project, a construction firm was designing a 60 km high voltage (HV) cable route to connect an offshore wind farm to an onshore substation. This entailed multiple cable sections of six cables, up to 1.3 km each. The project required a lubricant that produced the lowest friction and fastest installation time. The objective was to minimize pulling tension and side-wall pressure for each HV cable.

Measurements Helped Determine the Best Lubricant for the Job

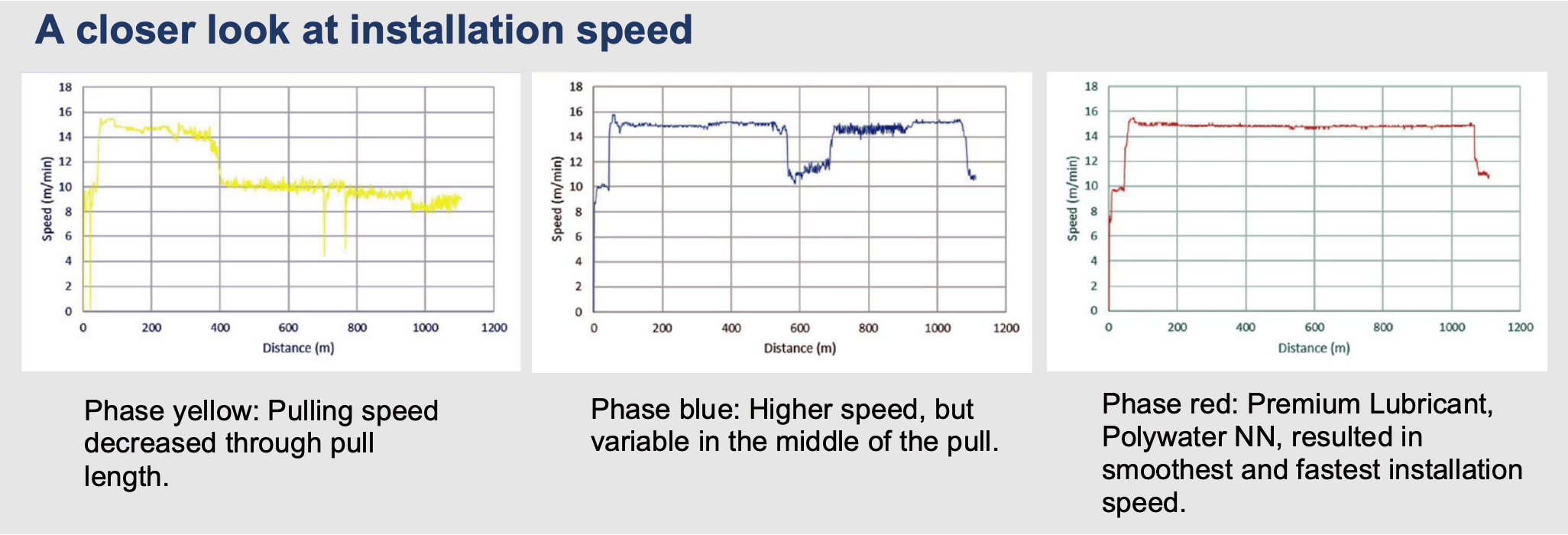

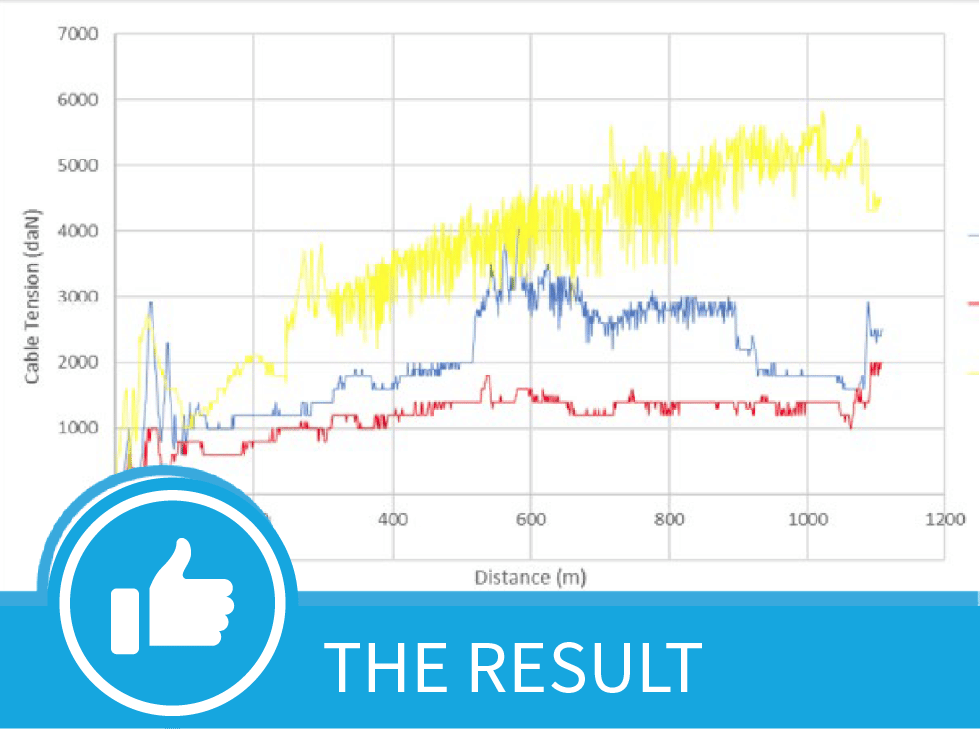

Three different grades of lubricants were applied and studied in phases: yellow, blue, and red. The section studied was approximately 1100 meters long with several bends. The duct was cleaned with a foam pig to remove excess water and was pre-lubricated. The lubricant then was hand-applied to the cable sheath at the section entrance. Lubricant performance was measured using installation tension and speed over the pull length.

Polywater NN Lubricant Produced Lowest Tension and Fastest Installation

Phase red, using premium Polywater NN lubricant, produced more consistent and higher installation speeds. This resulted in uniform installation without surging speeds or tension spikes in the cable, including the bends. Phase blue showed decent performance, but there was surging further into the pull (550 m) with a lower installation rate at that location. The blue pull showed three places with tension spikes (75m, 500m, 700m). Phase yellow produced a pulsing pattern partway into the pull at 350 m. Overall, the yellow phase lubricant produced higher tensions throughout and did not work as well for this complex and heavy pull.

The study showed that choosing the right lubricant for the project resulted in lower tension and faster installation, providing better protection of the cable and savings in time and labor.