Hawaiian Electrical Company (HECO) and the Pearl Harbor Cable Pull

How Polywater® Technology Helped to Plan and Pre-Measure the Mile-Long Pulls.

Overview

The United States Naval Base at Pearl Harbor, and U.S. Army and Marine air fields near Honolulu, Hawaii, on the Island of Oahu, serve as historical and spiritual symbols of the challenges faced by the United States during World War II and how they were met with courage and resilience. Historical sites around Pearl Harbor include Ford Island across the harbor, the USS Arizona battleship lying beneath the water, and numerous memorials and museums.

It therefore seemed fitting to create a multimillion-dollar U.S. Navy redevelopment project on Ford Island. A conference center, headquarters for oceanographic and atmospheric studies, museums, and housing units for civilian and military personnel were part of the ambitious plan.

Challenges

Meeting Energy Demands

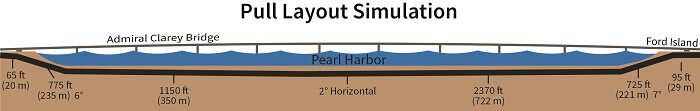

The project posed significant challenges in terms of providing adequate infrastructure and meeting energy demands. To provide enough capacity, it was estimated that a new substation was needed. This required two circuits (six cable runs) to be pulled under Pearl Harbor to Ford Island, almost one mile away.

The weight of the circuits and length of the pull presented unprecedented challenges. Each cable run was roughly 5300 feet (1615m) long. The cable was a 46 kV XLPE 1750 kcmil Cu with an OD of 3.04 inches (77 mm) and a weight of 7.625 lbs per foot (11.35 kg/m; reel weight of over 20 tons) to be pulled into a 6-inch (152 mm) OD SDR-11 HDPE pipe. The HDPE duct was in an exterior 24-inch (0.61 m) steel casing that was pulled (with the empty duct inside) under the harbor through horizontal directional drilling (HDD).

| Related Content: Evaluating a Historic Conduit for Upgrade |

Polyvinyl coated (PVC) duct. Fiber optic cable and smaller high-density polyethylene (HDPE) innerduct were pulled later into an empty duct in the casing.

Historical Site Preservation

As plans were developed, additional challenges arose based on requirements for historical site preservation. Extreme care was needed near the Ford Island runway where bullet holes from the Pearl Harbor attack, on December 7, 1941, were visibly marked in green.  The cable storage facility needed to be located away from these warplane bullet remnants. Underwater horizontal drilling for the casings presented risks of damaging the USS Arizona Memorial. In addition, the World War II submarine USS Bowfin exhibit was close to the bore entry pit, presenting risk of magnetic interference to equipment.

The cable storage facility needed to be located away from these warplane bullet remnants. Underwater horizontal drilling for the casings presented risks of damaging the USS Arizona Memorial. In addition, the World War II submarine USS Bowfin exhibit was close to the bore entry pit, presenting risk of magnetic interference to equipment.

The Solution

Partnerships and Coordination

It became obvious that an intense team effort among the various contractors was required. Each contractor was challenged to find the most advanced technology and equipment and to customize solutions as needed.

American Electric (AE), the electrical contractor that would do the cable pulling, calculated the pull layout and performed pull simulations to define the conduit run. At that point, a friction coefficient was needed to perform tension calculations, and this is when Polywater® became a critical player.

Measuring Friction & Polywater’s Pull-Planner®

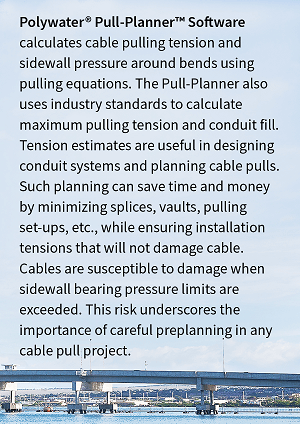

AE approached Polywater early in their planning to be a key partner in achieving successful cable pulls. An important tool was Polywater’s proprietary software program called the Pull-Planner, developed by John Fee, Polywater’s president at the time. The software’s primary benefit is the ability to easily change variables such as the friction coefficient, incoming tension, and conduit data for any given cable pull.

For the Ford Island project, the Pull-Planner software was used extensively during the pull analysis, which was part of the pre-planning steps. With a tension maximum on the cable of 12,000 lbs (54 kN), the software indicated the field friction coefficient would need to be below 0.28.

| Related Content: FAQ – Cable Pulling, Lubrication, and Tension |

Based on these calculations and using actual tension measurements from the onshore pulls (same cable but PVC conduit) the friction coefficient was assumed to be 0.17 (+/- 20%). This projected tension showed slightly over 7000 lbs (31 kN; 5800 to 8400 lbs). The analysis indicated the pull could be made with tensions well below the maximum.

How the Pull-Planner Works

Polywater research had determined the following primary influences on friction coefficient in the field and applied this knowledge to the Ford Island cable pulls:

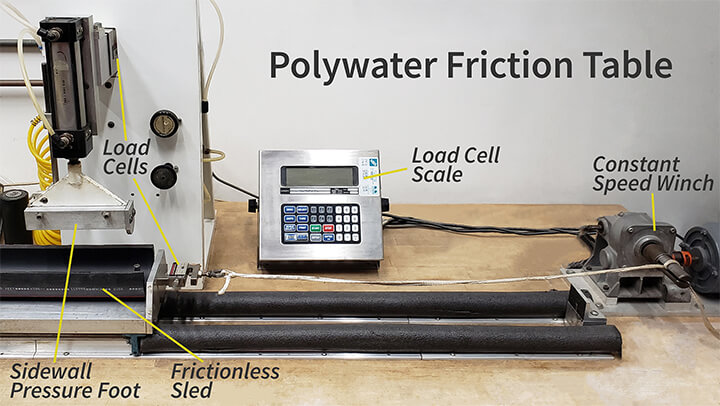

Jacket/Conduit/Lubricant—All three of these were known: the jacket was a PE type, the conduit was HDPE, and the lubricant was Polywater J, a product with decades of proven performance in the pulling of thousands of miles of underground transmission cable. Lab measurements on Polywater’s friction table with this combination had averaged 0.11 to 0.12, with a narrow testing range of 0.10 to 0.16.

Temperature—Higher temperatures make jackets “sticky,” even with a lubricant. Oahu’s average temperature in January is 72 degrees F (22 C). However, the team anticipated this to be only a small factor.

Number of Cables—Three cables pull with a higher friction coefficient than that projected by the weight correction factor, especially when cable fill is in the 30% plus range. This was not a factor since this was a single-cable pull.

Normal Pressure—Lubricated cables pull through bends with a somewhat lower friction coefficient than they show in straight sections. This difference is occasionally referred to as high bearing pressure versus low bearing pressure friction. The Polywater Friction Table is a high bearing pressure test (typically, 200 lbs/ft [300 kg/m] of bearing pressure). The magnitude of bearing pressure differences on friction depends on specific pull details. For the Polywater J lubricant, the size is differentiated at 20% to 30%.

| Related Content: The Polywater® Friction Table: Personal Perspectives |

Because the conduit “bends” under the harbor were very large radius bends, the only real force acting on the cable was its gravitational weight. It was determined that the pull was a “no bend” pull, presumably in the low bearing pressure mode of friction. This would be a significant factor pushing the friction coefficient above the friction table measurements.

Conduit and Pull Details—The conduit was clean and new HDPE with interior skived fusion joints. But could the lubricant carry the cable for that distance and still be effective? Even with optimal application techniques, the extreme length needed to be considered.

Back Tension—AE had an elaborate cable feed and reel driving system. They felt the cable would enter the duct with almost no back tension. Therefore, back tension was assumed to be zero.

Lubricant Application—AE was diligent in their planning and approach to lubrication, ensuring thorough and careful application. Polywater had developed algorithms for estimating lubricant quantities appropriate for a pull or multiple pulls on a job.

The recommendation for the 46 kV pulls was approximately 600 gallons (2270 liters).

Results

From early October 2005 to the end of February 2006, 24 pulls under Pearl Harbor were completed. After splicing, arc proofing, and grounding, power was available for the Ford Island project ahead of schedule. Today, almost 2 million people visit Ford Island annually where they experience memorials, monuments and museums important to the history of the United States.

A conscientious contractor was able to plan and execute a quality cable installation using the best research and technology available today. No visitors to this national historic site will ever know about or see the installation, and that’s all right. Pearl Harbor is not about power cables. Polywater is proud of the part they played in making this happen.

| Related Content: Coefficient of Friction in Cable Pulling — Part 1 |