How Oxygen and Acids Influence the Aging of Transformers

Technical paper focusing on the levels and interaction of oxygen (O2) and acids and their impact on transformer aging.

Key Takeaways

In this paper we will focus on the levels and interaction of oxygen (O2) and acids and their impact on transformer aging, including the following:

- Discuss how to monitor the impact of oxygen and acids on your transformer,

- Describe how transformer sealing design affects O2 levels inside the transformer and how excess consumption of O2 can speed aging, and

- Explain how acids can form inside the transformer when insulating oil interacts with oxygen and heat.

-

1. Introduction

As outlined in our article, How Temperature and Water Influence the Aging of Transformers, which focused on transformer aging behavior with oil cellulose systems, the aging of transformers can be accelerated by a number of factors. This paper walks you through the impact of oxygen and acids on the performance of transformers. There are ways to reduce the influences of these accelerators to mitigate and slow down the aging process in your transformer fleet. There are ways that you can use oxygen to the advantage of your transformer and there are measures that you can use to prevent accelerated aging altogether.

-

Related Content: Transformer Leak Repair Story from Polywater® 2. The influence of oxygen

Both O2 and nitrogen (N2) enter the transformer from the atmosphere. Oxygen is consumed inside the transformer and provides crucial information about the transformer’s condition and rate of aging. The age-accelerating effect of oxygen was identified in 1976 in a CIGRE paper (The oxygen-free transformer, reduced aging by continuous degassing)*. There are many potential entry points of oxygen into the transformer, but the principal means of entry is due to changes in the volume of oil as a result of temperature and load changes.

When operating temperatures of the transformer increase, the oil expands and its volume increases. The higher volume of oil acts like a piston to push atmospheric gases out of the transformer. When the temperature decreases, oil volume contracts and atmospheric gases are sucked back into the transformer. Different transformer sealing designs have been developed to prevent entry of O2 into the transformer during these volume changes. When assessing the gas content of transformer oil using Dissolved Gas Analysis (DGA), it is necessary to understand the sealing design of your transformer because the analysis of O2 will vary according to sealing designs.

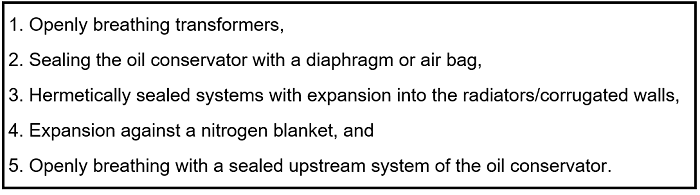

The following sealing alternatives are used within the industry:

O2 is consumed inside the transformer, so the O2 content will be in a balanced state between availability and consumption. So, typically the O2 levels in closed systems will be lower than in openly breathing systems. It is difficult to assess the gas content in openly breathing systems, as the gas exchange rate between the transformer tank and the atmosphere may differ by a factor of 1:10, depending on the design and configuration of the conservator.

Also, in open-breathing systems, concentrations of approximately 22,000-25,000 ppm can be regarded as normal. If the O2 content is less than 20,000 ppm, it is safe to assume that it is being consumed and that accelerated aging is occurring. Carbon dioxide (CO2) levels also can be used in the same way. CO2 levels in excess of 6,000 ppm are a clear indication of accelerated aging. If the O2 value is around 10,000 ppm, CO2 values in excess of 12,000 ppm can be reached in extreme cases. IEEE limit values do not apply to openly breathing transformers, and the CO/CO2 ratio is applicable to a limited extent.

The values found in closed systems with air bags or membranes will be completely different than those in openly breathing systems. Transformers with closed systems typically have a residual oxygen content of 2,000-4,000 ppm, combined with 1,500-2,000 ppm of CO2 in closed systems. However, if O2 is “0” and CO2 is above 4,000, it is again safe to assume the transformer is aging at an accelerated rate.

3. The influence of acids

The interaction of O2 and heat with the insulating oil in the transformer leads to the formation of acids in the oil. Acids are measured by the acid number expressed in “mgKOH/g.” This number indicates how much alkaline material (KOH) is needed to neutralize the acids in the oil. An acid number is a measure of the level of acidity and is the most important way to assess the condition of the insulating oil in the transformer.

Interfacial Tension (IFT) is also a useful indicator of oil quality. IFT is a measure of the difference in surface tension of oil, which is non-polar, compared to the surface tension of water, a highly polarized element. The IFT between two materials with similar polarity will be low. When mineral oil insulating fluid degrades through contact with O2, hydrophilic (water loving) acids, such as carboxylic acids, are formed. These are highly polar and are not very soluble in oil due to the oil’s low polarity. The presence of hydrophilic acids in the oil increases its polarity and results in lower IFT. Low IFT indicates the presence of both acids and water, which can affect the dielectric properties of the oil and generate sludge in the transformer.

Both acid number and interfacial tension need to be considered together. For example, a high acid number, e.g. 0.2 mgKOH/g, will typically lead to an interfacial surface tension of less than 20 N/m.The standards specify limit values of 0.1 mgKOH/g for transformers above 70kV and 0.25 for those below. The latter value is nonsense as the chemical effect is independent of the operating voltage. Besides, sludge precipitation commences beyond the value of 0.1, which can reduce the transformer’s cooling capacity and operational safety. Therefore, remedial actions make sense at a value of 0.1.

The rate of acid formation can be used to assess the transformer’s internal cooling system design and aging rate. A high rate of acid formation means that the oil is thermally stressed, which causes the oil to degrade at a faster rate. This can be an indication of inadequate cooling due to poor design. The “delta (Δ) of acid formation” can be used as an indicator of both the proper design of the internal cooling system and the aging rate of the transformer. Acid also actively attacks the cellulose insulation and will accelerate its decomposition. This is evident from increased O2 consumption in the decomposition process in the presence of acidic oils.

-

4. Combination of oxygen and acid

Oxygen and acid work in unison and must be evaluated together. This means that both products need to be addressed in an effort to maintain aging transformers. Both O2 and acids degrade the paper (solid) insulation inside a transformer. In fact, O2 consumption is a very good indicator of the system’s overall aging rate. High O2 consumption means faster paper solid insulation degradation. O2 consumption typically decreases after oil regeneration, so one would expect that the rate of paper degradation would slow as a result.

However, oil regeneration often results in continued acidic degradation of paper insulation. The rate of acidic degradation of cellulose depends on the concentration of water and on the concentration of H+ ions split from acids. Many of the acids formed in transformer oil and in the degradation of cellulose are absorbed in the paper. So even when oil regeneration removes O2 from the system, the acids that still remain in the paper insulation continue to degrade the cellulose and create a pathway to faster oxidation as illustrated in section 6.2. It is also important to evaluate production of acidity together with the CO2 and O2 content as shown in example 6.1.

-

Related Content: Cost Effective On-Site Leak Repair of Power Transformers 5. What remedies are useful and when?

5.1. Addressing the O2 issue:

It’s helpful to equip transformers with sealing systems that impede oxygen ingress, airbags in the oil conservator, or upstream sealings between the oil conservator and the atmosphere. Partial degassing systems have also proven their worth for the refurbishment and conservation of older openly breathing transformers, reducing the proportion of atmospheric gases (N2, O2) to approximately 30% of saturated values.

The systems above also remove water from the cellulose. The task is how to solve this issue from technical and economic points of view. In older open-breathing transformers, bypass or regeneration plants are a well-proven method to reduce O2 in the oil. Oil is taken from the lower part of the transformer, degassed, dried, and sent back to upper part. Since standard connections like oil sample cocks can be used to switch the regeneration system between different transformers without shutting them down, one regeneration unit can treat two to four middle-sized transformers in three- to six-month cycles. This results in a reduction of the oxygen availability and a decline in the aging rate. Therefore, maintenance costs are minimized since no repair work is necessary on the transformer, like a change of the conservator. Since the oil is dried, any water in the system is drained from the transformer.

5.2. There are three ways to address the issue of acidity:

– Filling the transformer with inhibited oils versus uninhibited oils. You should avoid using uninhibited oils. The inhibitor acts much like an anodic corrosion protection coating in steel structures. It will shield the oil from oxidative degradation to prevent the generation of acids in the oil. Most oil inhibitors contain 2, 6-ditertiary butyl Para-cresol (DBPC; BHT) and 2, 6-ditertiary butyl phenol (DBP). Oils without these inhibitors will degrade faster and require frequent oil changes, which can be time consuming and costly.

– As soon as 0.1 mgKOH/g is reached, the oil needs to be regenerated, followed by oil inhibition even if the oil was not originally inhibited. It is against best practices not to inhibit the oil after regeneration, as the freshly regenerated oil no longer contains any age-stabilizers.

– Correct transformer design to avoid thermal stress on the oil. In our previous paper, How Temperature and Water Influence the Aging of Transformers, we discussed that correct thermal design means that for transformers expected to undergo frequent load changes, the internal cooling system must eliminate temperature spikes during rapid load increases, i.e., OD (Oil Directed) cooling. For transformers where the oil needs to be pumped, e.g. OFWF (Oil Forced/Water Forced), or in the case of remotely installed oil to air radiators, the cooling in the windings must be based on an ON (Oil Natural) design so that the oil temperature is distributed as evenly as possible inside the winding system.

-

Related Content: Mapping Transformer Populations 6. Examples

6.1

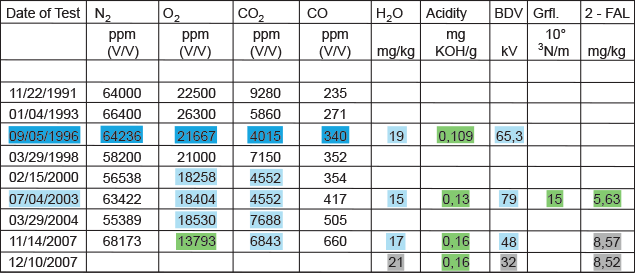

In the case below, the very low oxygen content is conspicuous. It was reached immediately after commissioning. From 2004 it was included in the transformer population’s preservation program even though the transformer was in prime condition. As shown below, the acid content appears to be increasing quickly and has reached the regeneration threshold (0.1 mgKOH/g) in only 9 years. This means that the thermal stress in this transformer has led to a rapid loss of oil quality.

6.2 Example of interaction of acid and oxygen

Grid coupler 250MVA 220/110 kV

This transformer is an excellent example showcasing the interaction of acid and oxygen. The transformer went into accelerated aging after 2000 and reached its End of Life (EOL) stage in 2007. Until 1993, the O2 >> 20000 content was typical for a properly working open-breathing transformer. Nevertheless, the CO2 content was high indicating a high level of O2 consumption. In 1996, O2 dropped and acidity was 0.109 mgKOH/g, which was at the maximum limit. From 2000 on, the O2 content continued to decrease while the acidity increased. Additionally, in 2003 furan levels of about 5ppm were found.

In 2007, all indicators showed that the transformer had reached an End of Life (EOL) condition, including the following values:

- Low O2 (13000 ppm),

- High CO2 9ppm furan,

- Unacceptable breakdown voltage (32kV), and

- high water (21ppm).

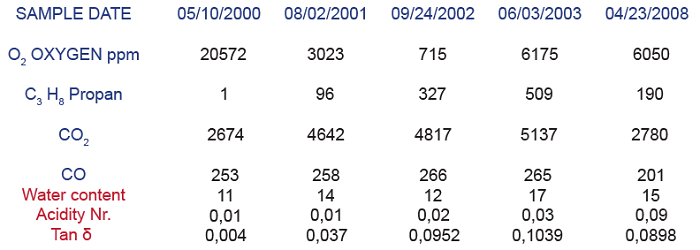

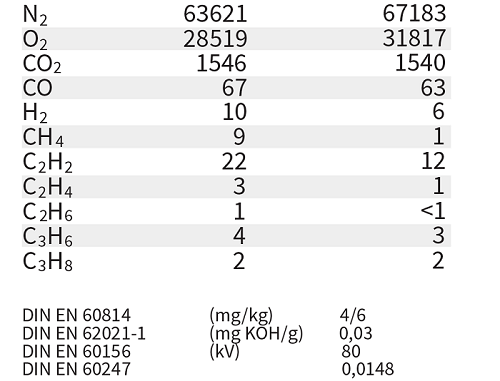

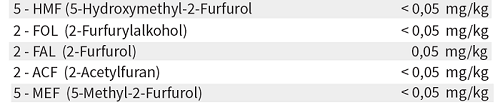

6.3 Profile of a grid transformer built in 1969: 110/20kV 31.5 MVA; openly breathing type.

The values in the table below show that the transformer, which was properly designed, was still in an excellent condition after more than 30 years.

The Acetylene (C2H2) is caused by mixing the gases of the On-Load Tap Changer (OLTC) in the common air space in the conservator. This transformer is a good example of proper design showing good values and a practically new condition.

The 1969 transformer had the following values:

- saturated values for N2 67621ppm),

- O2 (~ 30000ppm),

- and a CO2 below 2000 ppm, and

- Very low C2 and C3 gases and no furans.

DGA from 2003-2009

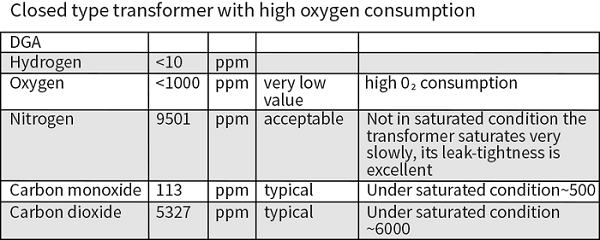

6.4 Example of a closed-type transformer with high oxygen consumption.

The high oxygen consumption of the transformer below suggests an unfavorable long-term prognosis. The transformer failed three years after the analysis.

It was very difficult to evaluate this transformer because the owner made regular degassing treatments. To understand the transformer’s condition, O2 and CO2 should be considered together. The consumption of all available O2 (0) with high CO2 (6000) for this transformer’s closed-type design showed rapid aging. Since the gasses were minimized and had to re-saturate, it was a good indicator of internal processes.

The aging accelerators of acid and oxygen work in unison to promote aging of the oil-cellulose system. Both factors depend strongly on transformer design, particularly, in the design of the internal cooling system.

A self-reinforcing cycle is often generated in which the following takes place:

- High oxygen consumption accelerates the aging process,

- The aging process produces acid, which increases oxygen consumption.

As these two elements work together to accelerate transformer aging, you must make sure that the transformer’s cooling system is properly functioning and properly designed. The second good practice is to avoid the use of uninhibited oil. Thirdly, you need to prevent oxygen ingress.

Whether your transformer is openly breathing or sealed against the atmosphere, if it is properly designed and you adopt mapping as a predictive maintenance practice, you can achieve a longer lifetime for your fleet.

| For solutions on repairing and maintaining transformers, visit Polywater® PowerPatch® Transformer Leak Repair System |

Have any questions?

*The Oxygen-free Transformer, Reduced Ageing by Continuous Degassing, W. Lamp and E. Spicar, presented during the International Conference on Large High Voltage Electric Systems (CIGRE), Sept. 1976