How Lab Testing Improves Utility Pole Field Performance

In the utility industry, field performance is where products prove their worth. But what happens when a product fails mid-job and leaves a lineman stranded 50 feet (15 m) in the air? This real-world story shows how that failure turned into a breakthrough. Learn how lab testing, real-time feedback, and product iteration led to a safer, smarter solution for utility pole repair—and a win for field crews and engineers alike.

Product Trials in the Utility Industry: Field Conditions Matter

During a new product trial at a midwestern utility, a product weakness was quickly discovered. Jake Jonnes was demonstrating the new product to a contract crew of linemen. They were repairing transmission lines. Transmission poles are expensive to replace. It is better to repair and maintain the poles. For this utility, the land is hilly and rocky, and it is difficult to get to the poles. That’s another reason they opt to repair the poles.

For Jake, this was a memorable field trial. “We had to take an all-terrain UTV to get into the wooded site. There was a whole line of utility poles and a crew of four linemen working with a competitive product. And of those four guys, only one was a normal size. One guy was about 130 pounds (59 Kg), and, like a squirrel, he could climb like crazy. The guys on the ground would pass up materials using a rope. They were working in pairs with one guy on the pole and the other one sending up materials. The guy on the pole would finish and leapfrog to the next one. They were just throwing down empty cartridges, or empty bags of whatever product they were using. We saw this was a big job with a lot of opportunities for us.”

Recognizing Real-World Application Challenges

Recognizing Real-World Application Challenges

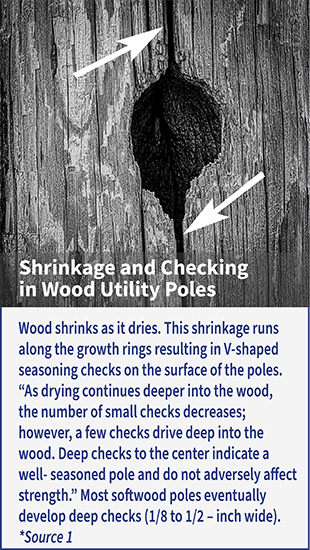

Jake continues, “When we got our trial, the lineman went up the pole and we gave them our product. There were a lot of holes. You would get a big round hole with a crack running through the bottom and down the pole. In addition, the poles aren’t smooth. If there is a gap where the pole is wrapped or because of the cracks from the pole checking (see image), the product would leak out.”

Field Feedback as a Catalyst for Product Development

“It didn’t take very long before one of the guys was up on the pole. It was an H-frame: two poles connected by a cross-arm. This guy was about 50 feet (15 m) up and I could hear conversation between the guy on the ground and the guy up above that. Things weren’t going well. You could see the product leaking through the cracks or between the gaps in the wrapping. It was getting onto his gear and his clothes.”

Pretty soon the ground support crew was sending up another piece of equipment. It turns out, our product leaked onto the lineman’s fall protection equipment. Fall protection equipment is a critical piece of safety gear. If the lineman falls, it catches him and arrests the fall. The leaking material had gummed up the fall protection straps so that the lineman couldn’t get unclipped from the pole. The lineman was stuck and was eventually able to unclip and use the replacement gear.

Understanding End Use and Asking the Right Questions

Knowing that the field trial was not going well, and the customer was not super pleased, Jake started cleaning the gear with some Grime-Away. Once the lineman got back to the ground, the feedback was not good. But the effort to clean the equipment and get it back to working order allowed Jake to ask a few questions:

• What needed to be remedied?

• What characteristics are we looking for?

• What do they like about how the product works?

• What don’t they like about the current product?

With this information, Jake was able to take the product back to the laboratory to rework the formulation.

| Related Video: Utility Pole Repair Solution |

Designing Lab Tests That Mimic Utility Field Conditions

Right away, we understood that we needed to have a faster gelling product. We needed the resin to set up before it leaked down the crack or through the imperfection and onto the installer. Getting the right gelling rate was key. Since there were no standardized tests for this performance characteristic, a new test had to be developed.

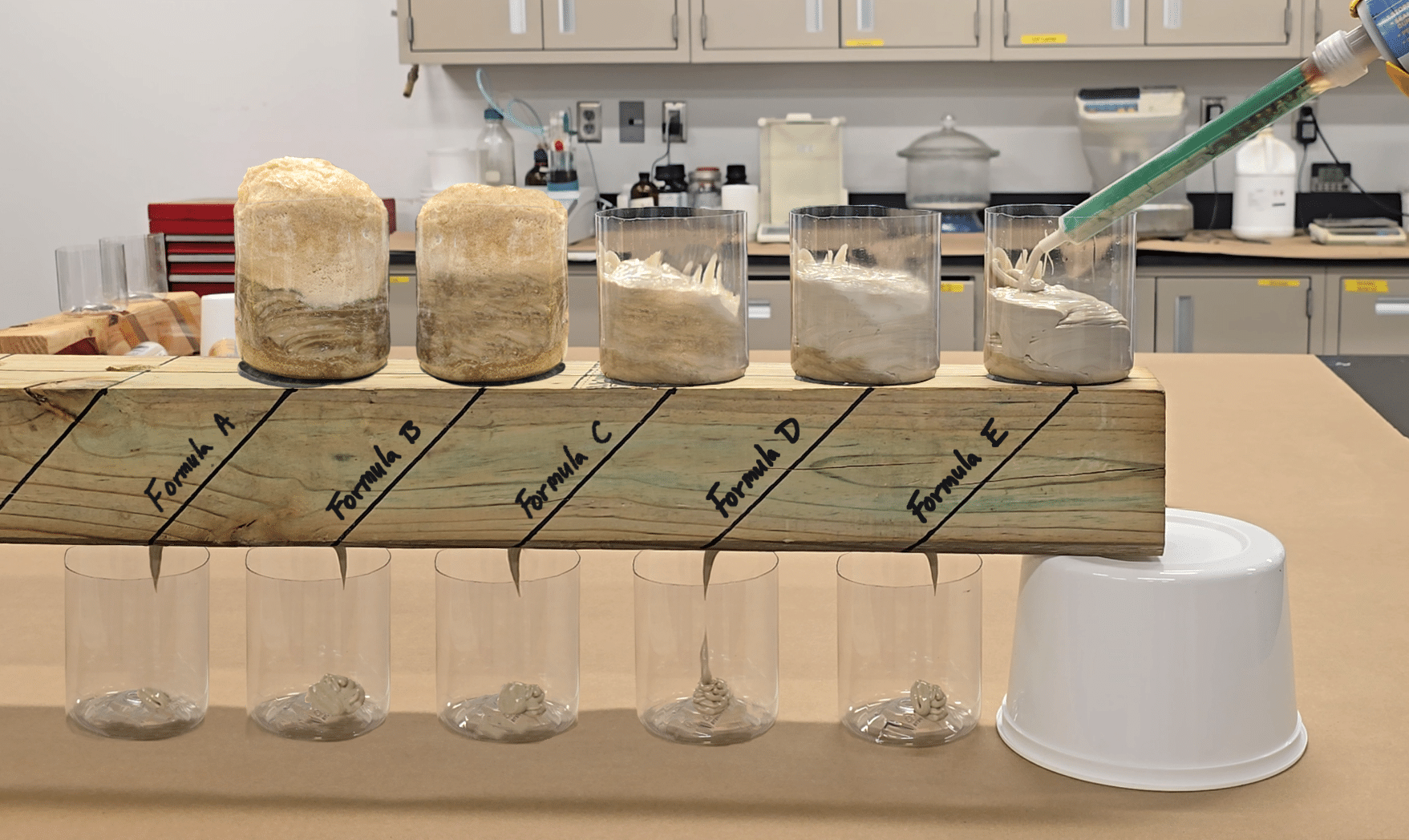

During test development, multiple ideas were explored. We chose a test that best mimicked the field conditions. A wood testing device was built to measure product flow and gel characteristics. A series of angled holes were drilled into a length of 4X4 (90 mm X 90 mm) lumber. The wood is marked with a center line and cross lines at regular intervals of 6 inches (15.2 cm). A 45° angle is drawn on the side of the lumber for a visual reference. An extra-long, ¾-inch (19 mm) spade bit is used to drill the spaced holes. In addition, a ½-inch (12.7 mm) hole is drilled into a 16 fl. oz (473 ml) cup. The prepared test cup is centered over the ¾-inch (19 mm) drilled hole and adhered to the testing device. Once completed, the wood device is propped up over catch pails.

Measuring Performance: Sealant Gelling and Leakage in Lab Tests

A full 250 ml cartridge is dispensed through the mixing nozzle into the test cups. Material will fill the test cup, begin to react and flow through the drilled holes. Any excess material will drain into the catch pail. The weight of the material dispensed is recorded as well as the quantity that flows into the catch pail. A good test fills at least part of the drilled hole. Less than 25% of the starting material should flow into the catch pail.

This was deemed a good test because it is relatively easy to run, and the results are reproducible. Having a good test to reflect field performance is key to a strong product development process. In this case, it took dozens of iterations to get the product right. Other factors had to be considered as well, for example: the density and strength of the finished foam or the ability to pump material through the mixing nozzle without clogging. Performance at different temperatures and conditions had to be tested as well.

The flow test is just one testing parameter, in this case, a key parameter for product performance.

| Related Content: How Polyurethane Foams Work: Chemistry, Customization, and End Use Applications |

From Lab to Field: Retesting the Improved Product

It was over a year before Jake was able to take the new product back to the customer. He was expecting a fresh start. As soon as Jake got out of the truck, he explains, “there’s the same guy that I glued to the pole. It was a sinking feeling knowing that I was going to be working with the same guy and that he might have a biased opinion going into this trial.”

This time, the trial went very well. There was no mess. It filled the hole and everything worked as planned. Jake demonstrated the product to the ground crew leader, and he was pleased. Jake reports, “I took a calculated risk and said that’s great, but I’d like to get the opinion of the guy I got stuck to a pole 13 months ago.”

He could have said, yeah, I don’t like this stuff, I prefer the competitive product. This is a common response for linemen. The bad experience gets stuck in their head, and they have no problem sharing their feelings. They’re very honest. Instead, the lineman said, “It seems like you guys got it figured out.” And at that point the deal was done. We earned our new customer.

*For visual purposes only. Lab test results do not exactly mimic in-field results with use of all UPR Kit components and proper procedure.

Field Techniques to Ensure Sealant Success on Utility Poles

We developed an installation method for them as well. Wrapping the pole 6 to 12 inches (15 cm to 30.5 cm) below the hole eliminates any mess. You can see how it works in the testing. The product gels and seals the opening. If you have a good “no-flow” product, it’s not going to flow much more than 6 inches (15 cm) and then if it goes any further, it’s because it’s expanding. It’s pushing down into the crack as intended.

| Related Content: Polywater® UPR™ Wood Utility Pole Repair Overview Video |

Delivering a Total Solution for Field Crews

It isn’t just about developing a product. It is about understanding how the product is used. What do the users need, and what are the challenges? It is about developing the whole package and the installation method. There are so many variables when developing a product. It’s not just the solvent or the adhesive or the sealant formulation. It’s the packaging. It’s the nozzle. It’s the tool. It’s the total solution. The total solution is more than just throwing a product in a can. That’s the difference; that’s the advantage of these products.

Continuous Improvement: The Future of Field-Proven Products

It is important to understand the challenge of the job so that you can develop a product and method to make it easier, safer, and faster. Jake says, “After working on the pole repair compound, my confidence grew. There’s a nuance to the application. And that’s why product development never really ends. You are constantly learning new things as you work through the process.”

Have any questions?

- *Source 1

Morrell, Jeffrey. “Wood Pole Maintenance Manual: 2012 Edition”. December 2012. Corvallis, OR, Forest Research Laboratory, Oregon State University. Contribution 51. P. 7.