How Polyurethane Foams Work: Chemistry, Customization, and End Use Applications

The article discusses the chemistry, customization, and end-use applications of polyurethane foam. Polyurethane foam is a versatile material used as a structural building component, molded part, flexible cushion material, and adhesive/sealant. The article describes the chemistry of foam and other additives that can be used to customize the material for a specific purpose such as duct sealing. The density, speed of cure, fire retardants, and cell type are some of the properties that can be adjusted to fit the end use. The article also discusses packaging and application, physical and performance testing, and the comparison of one-part aerosol sealants with two-part polyurethane foam.

Polyurethane foams are versatile materials used as structural building components, molded parts, flexible cushion materials, and adhesive/sealants. They are a part of our everyday life. Polyurethane foams represent a wide class of materials that can be formulated with specific characteristics for a particular end use. When specially formulated, they can be extremely effective sealants. Such sealants are commonly used in the areas of electrical and communications installations (e.g., as conduit sealants).

What is the Chemistry of Polyurethane Foam?

Polyurethane foam is produced through an exothermic reaction between an isocyanate and a hydroxyl-containing compound, typically a polyol. The polyol structure influences the amount of cross-linking and flexibility in the finished resin or foam. Often, there is a secondary reaction with water that drives additional properties. The water and isocyanate release carbon dioxide which generates foam and cures into a polymer structure. Important modifiers of the reaction are the catalyst and gelling agent. These determine the speed of the reaction and can act to balance the water reaction as well.

| Related Content: Why DIY Store Foams Fail to Seal Conduits |

Other Additives Used in Polyurethane Foam

Other additives add character to the polyurethane foam so that the final formulation can be designed specifically for the end use. These include:

-

- Fire retardants

- Surfactants, compatibilizers, or adhesion promoters

- Foam stabilizers or cell openers

- Plasticizers

- Cross-linking agents and chain extenders

- Fillers

How Does Polyurethane Foam Work? The Chemical Reaction Explained

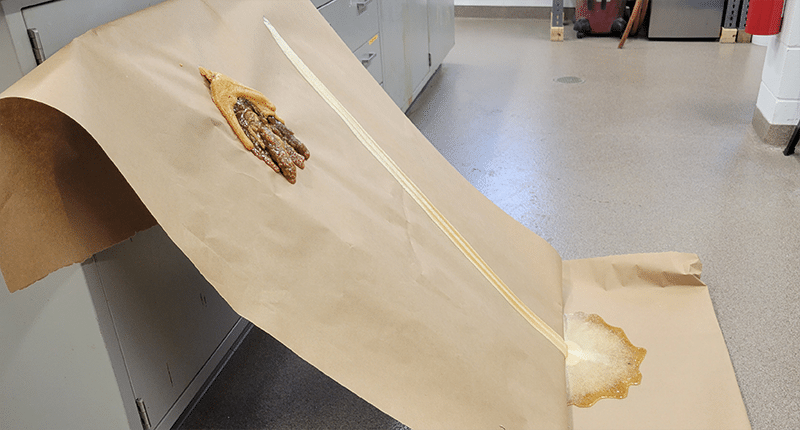

Polyurethane foam is the result of a chemical reaction when its two components are mixed. The basics of the reaction are the expansion and gel phase. During the initial reaction phase, a small amount of CO₂ gas is released and trapped in the liquid mixture. This creates small bubbles. As these bubbles multiply and expand, the mixture also expands or rises. The more the liquid foams in this initial reaction phase, the less dense the material. The resin then cures and hardens around the bubbles, creating a uniform matrix of cells. This cellular structure is strong. When the cells remain closed, the structure is watertight and airtight.

Customizing Polyurethane Foam for End Use Applications

Foams can be customized to end use, and there are thousands of iterations in the marketplace. By understanding end use requirements, the foam chemistry can be adjusted and tailored to fit the purpose. Following are just a few common considerations:

| Related Content: Duct Seals Prevent Ruinous Water Damage |

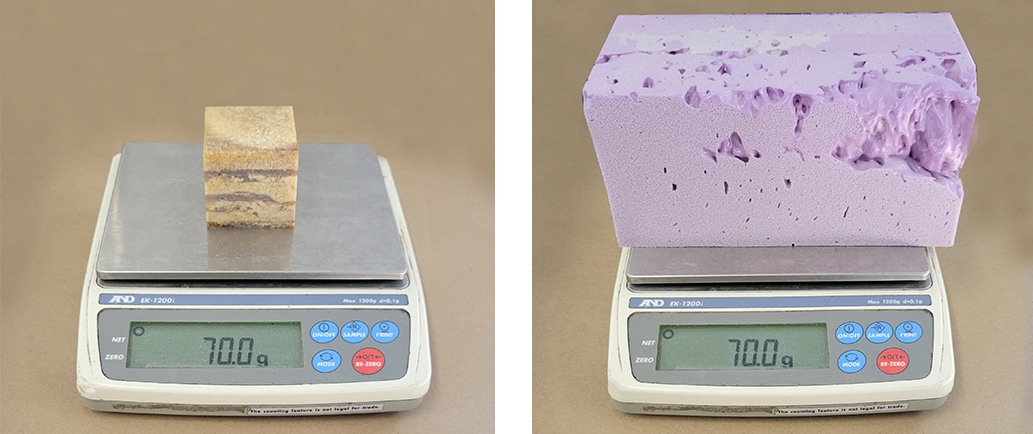

Density Considerations

This basic characteristic will determine how light or heavy the material will be. The advantage of low-density foams is that a small amount of starting material will fill a large space. Lightweight foams can be cost-effective. On the other hand, dense foams can be extremely strong and durable.

Flow and Speed of Cure

The reaction rate is controlled by a few variables. It is possible to design fast gelling into the reaction. This can quickly limit the flow of the liquid before it starts to set. Because a bit of flowing is sometimes helpful, it is also possible to slow the cure just enough to allow the liquid material to spread into all the spaces that need to be covered and filled.

Fire Retardants

Polyurethane foams can be used to block air flow and seal spaces in buildings. In addition, it is possible to add fire retardants to limit the spread of smoke and fire. Polyurethanes designed with this feature will self-extinguish.

| Related Content: Why Does Duct Putty Fail to Seal Conduits? |

Closed Cell vs Open Cell

The bubbles in a foam are referred to as “cells”. A fully intact cell is called a closed cell, and an open cell is therefore one that has a connecting opening to another cell(s). The higher the closed-cell content, the more watertight and airtight the foam (typically preferred for sealants). In some cases, the preference is to open the cells to allow air and water to flow through the foam. This can also give the material some elasticity. It can also allow water to drain through it (e.g., a spongy dishwashing scrubber). For applications requiring airtight or watertight performance, a closed-cell foam is a must.

Packaging and Application of Polyurethane Foam

The components of the polyurethane foam must be well mixed to initiate the reaction. This can be done mechanically with a mixer. For products used on site, polyurethane foams are available in convenient packaging such as side-by-side “burst pouch” mixing bags. They can also be dispensed from cartridges through a static mixer. In this package, the two parts must be volumetrically balanced and should combine easily to ensure proper mixing. Developing this total package solution is done through the formulation as well as the mixer design. The viscosity of the unreacted components influences the ease of dispensing as well as how thoroughly the two mix through the static mixer.

Physical Testing of Polyurethane Foam

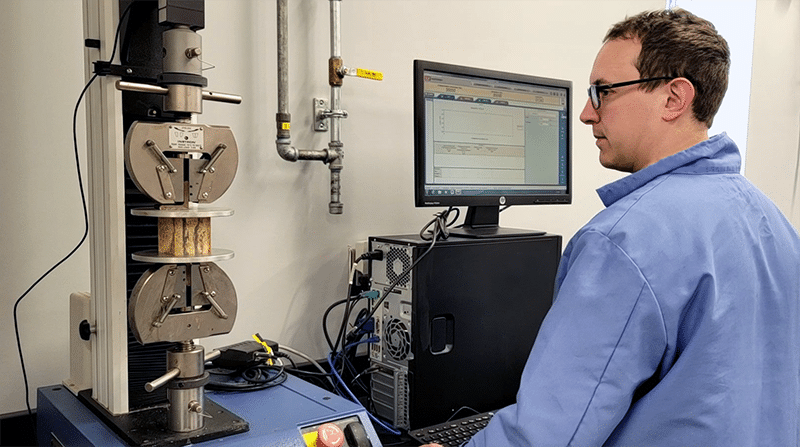

Polyurethane foams can be formulated to have excellent adhesion to different surfaces. They can be very strong and rigid or soft and flexible. Polyurethane can be tested for density, moisture absorption, compressive strength, and tensile strength.

Performance Testing of Polyurethane Foam

Testing specifically to the end use is key to ensuring proper performance. This can include hydrostatic testing, air flow testing, fire, and chemical resistance. It is also important to test compatibility with any components the foam remains in contact with, such as cable jackets.

One-Part Foams: A Comparison

One-part aerosol “gap and crack” sealants are very common at DIY and hardware stores. These one-part foams are very different from the isocyanate/polyol two-part systems discussed above. One-part foams depend on aerosol propellant for virtually all of their expansion. Following this expansion, these foams depend on available environmental moisture to cure the resin and create strength. The overall strength of these one-part foams is often far inferior to that of isocyanate/polyol two-part foams. Some common characteristics include:

-

- Low-density, lightweight foam

- Limited cured depth of 3-4 inches (7 –9 cm)

- Long cure cycle

- Higher open-cell content

| Related Product: Polywater® FST™ Foam Duct Sealant |

What Makes a Good Polyurethane Foam?

Because an infinite number of formulations is possible, polyurethane foams can be tailored to fit the purpose of very specific applications. Variations can address cure rate, flow dynamics, reaction temperature, component compatibility, final density, cell structure, fire retardancy, elasticity, tensile strength, and a host of other desired characteristics. One-part, open-cell foams available from DIY stores are designed as inexpensive options for the broadest possible range of end uses. However, this also tends to make them less than ideal for any single application. Why buy adequate when great is available? For sealing critical infrastructure, such as expensive electrical or communications cables in conduit, where robust, watertight protection is required, a “good foam” is better defined as a two-part, closed cell mixture designed and tested specifically for that environment. Any perceived savings from cheap, one-part, open-cell foams quickly vanishes when the cost of failed seals and the resulting damage is factored in the equation. Thus, it makes sense to seek out foam manufacturers capable of producing targeted formulations for optimal performance.