FAQ – Expanding Foam Duct and Conduit Sealing Applications

The most frequently asked questions about conduit sealants and duct sealing applications.

Are expanding foam duct sealants safe to use?

All chemicals come with some risk. Some individuals may be more sensitive to some compounds than others. When used in accordance with manufacturer recommendations, Polywater® FST, Polywater® AFT and Polywater® ZipSeal™ duct sealants are safe to use.

| Learn more about Urethane Safety: MDI Monitoring on Polywater® Foaming and Non-foaming Urethane Products |

I need a UL or CSA approved duct sealant. Is yours approved?

UL and CSA do not have specific tests for “conduit sealants.” However, Polywater conduit sealants were specifically formulated to seal conduits from water and gas intrusion and be rodent resistant to protect systems from disruption. Electrical codes in North America do call out specifications for conduit sealing and list that they:

- shall be compatible with all parts of the wire and jacket materials

- must prevent moisture and gas ingress

- be installed where temperature change occurs

- be installed in underground locations at one or both ends of the conduit.

Electrical codes in other regions of the world often share many of the mandates seen in North American codes. Check your local regulations to verify code language. When applied in accordance with manufacturer instructions, Polywater foam duct sealants generally meet electrical code requirements for conduit sealing, although some AHJs (Authorities Having Jurisdiction) may require official recognition of a specific performance characteristic by an outside testing agency or manufacturer documentation to claim compliance.

Are Polywater duct sealants UL listed?

“UL Listed” is the certification for whole products that are meant to be used on their own. The “UL Recognized” certification is for component parts meant to be incorporated into a larger whole. In the Classification service, UL determines that a manufacturer has demonstrated the ability to produce a product complying with UL’s requirements with respect to a specific risk, such as casualty or fire.

Polywater AFT is UL Recognized. Polywater FST is ULC Classified.

Does it cost a lot of money for just one use?

FST, AFT, and ZipSeal 2-part expanding foam sealants typically cost less “per seal” than most other sealant technologies because multiple applications may be made from one reusable cartridge or aerosol can package.

How many conduits can you seal with foam sealants?

Foam sealants expand to fill the empty space between the cable or cable bundle and the inner wall of the conduit. The number of seals one can perform depends on the amount of sealant available in the package and the size and fill percentage of the conduit.

| Use Polywater’s FST Foam Quantity Calculator to Make Estimation Easy |

AFT and ZipSeal sealants provide usage quantities in their packaging. The AFT aerosol sealant can seal anywhere between one 8-inch (203 mm) and fifteen 2-inch (51 mm) ID conduits. Each ZipSeal cartridge can seal between five 2-inch (51 mm) and fifteen 1-inch (25 mm) ID conduits.

Are Polywater duct sealants fire-rated?

FST duct sealant is fire-retardant under UL 94 and is UL classified under caulking and sealant surface burning characteristics in both the US and Canada.

AFT duct sealant is UL Recognized to meet UL 94 with a Class HBF flame-retardant rating.

ZipSeal is also flame-retardant.

Can I use foam sealant in a Class 1 Div 1 application?

No – Sealants and fittings are approved in combination for Class 1 Div 1 applications. You must use the combination of fitting and sealant that was tested to obtain the certification.

Does FST dissipate heat?

Duct seals can act as insulators. This is not a concern in terms of heat dissipation since the seal is a small fraction of the

cable run.

- FST seals are in contact with approximately 3” (7.6 cm) of the entire cable surface.

- AFT seals are in contact with approximately 6” (15 cm) of the entire cable length.

- ZipSeal seals are in contact with approximately 2” (5 cm) of the entire cable length.

Do foam duct sealants stop mice and rats?

Polywater expanding foam duct sealants provide hermetic seals that do not allow rodents to smell food sources through the seal. They are excellent deterrents for rodents.

Will duct sealant crush the cable or burst the conduit when it expands?

No – Expanding foam duct sealants do not have enough expansive strength to crush the cable or burst a conduit. If extraneous sealant is applied, it will seep through the path of least resistance, which are the damming materials at the mouth of the conduit.

Can you use foam duct sealant around the outside of ducts in wall penetrations?

Expanding foam sealants may be used to seal the outer perimeter of conduits through wall penetrations when fire blocks are not required. The void must be enclosed by damming materials during the application of the sealant, which may be removed after full cure. For large voids, sealant may need to be applied in stages to ensure proper expansion and finished foam density.

Can you apply foam conduit sealant in vertical applications?

Polywater FST, AFT, and ZipSeal duct sealants can be applied to vertically oriented conduits.

FST and ZipSeal are liquids when first expelled from their cartridges. The foam damming strips provided in the FST kit instruct users to create a chamber into which the sealant is injected. These damming strips contain the FST sealant in liquid phase during its expansion and curing process to allow installation in any orientation. ZipSeal kits provide an innovative Zip-Disc™ into which the sealant is injected. This Zip-Disc contains the sealant as it expands and cures.

AFT aerosol sealant foams and expands immediately to allow clean and easy use in vertical applications.

How can I install conduit sealant vertically?

FST may be applied in vertically oriented conduits. Ensure that the foam damming strips provided in the kit are inserted into the conduit creating a 3″-long (7.6 cm) cavity between them. Inject sealant by passing the nozzle between the layers of the damming strips at the mouth of the duct.

| View FST Application Instructions |

ZipSeal kits incorporate the use of a Zip-Disc that is saturated with sealant to block the conduit. Size the Zip-Disc by adding to or removing the outer layers to match the size of the duct, and insert it into the mouth of the duct. Insert nozzle tip past the outer layer and into the center black mesh of the Zip-Disc. Place full injections about ½-inch (1.3 cm) apart throughout the disc. Each injection must be in a different location.

| View ZipSeal Application Instructions |

AFT foams immediately and may be injected into vertically oriented conduits without fear of mess. First, place damming material approximately 6” (15 cm) into the conduit. Invert the AFT can and insert application nozzle deep into conduit. Spray foam for recommended number of seconds in accordance with the application instructions. Place a gloved hand or cardboard at the bottom end of the conduit to prevent the expanding foam from escaping the mouth of the duct for approximately 2 – 3 minutes at room temperature.

| View AFT Application Instructions |

Do I have to use both damming strips to vertically apply conduit foam sealant?

It is always best to use both FST damming strips to contain expanding foam. Damming the foam ensures adequate pressure and contact between the expanding foam and the surfaces to which it must adhere, providing a robust seal.

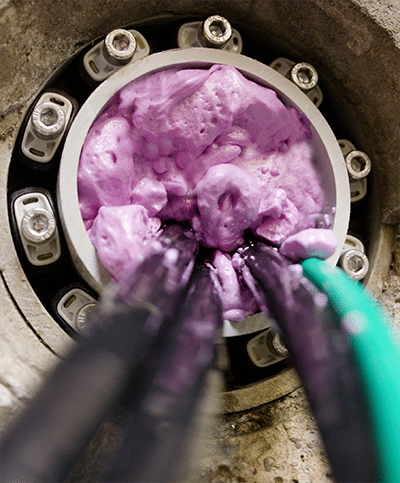

Do I need to separate the cables when applying duct foam sealant?

Separating the cables inside the conduit creates a higher-quality seal around each cable. Damming strips are used to separate the cable from the conduit wall as well. This allows the injected foam to fill all the spaces and fully adhere to all cable and conduit surfaces. Foam damming strips are provided in FST duct sealant kits for this purpose.

How long does foam conduit sealant take to cure?

Foam sealants cure in function of ambient temperature but will not cure below 40° F (4° C). Foam sealants are quick to install in normal working conditions: Foaming expansion is complete within 8 – 9 minutes @ 40° F (4° C) and 4 – 5 minutes at 70° F (21° C). A hard, non-sticky skin forms within 15 – 18 minutes at 40° F and within 7 – 9 minutes at 70° F.

Can I move the wires around after I inject foam conduit sealant?

Wires and cables should never be moved after injection of foam sealant. Adjust and position cables prior to sealant installation.

Can I reuse the nozzle?

A single nozzle can be used for multiple seals completed in immediate, consecutive applications. Do not allow the nozzle to rest more than one to two minutes between injections. For most other installations, the nozzles are single-use items since the 2-part foam mixes and cures inside the nozzle.

We like duct putty because it’s easy to remove. How easy is it to remove FST foam duct sealant?

Duct putty is easy to remove because it does not block conduits robustly. FST, AFT, and ZipSeal seals may be removed by piercing the foam around the inner wall of the conduit with a long-handled screwdriver to loosen the bond. After the foam has been weakened, it can be pulled out and removed from the cable.

How do I remove Polywater foam duct sealants?

FST, AFT, and ZipSeal two-part expandable foam duct sealants may be mechanically removed by piercing the entire outer circumference of the seal with a rigid tool such as a long screwdriver. Once the junction of the seal and conduit wall has been loosened, the entire plug may be pulled out and broken free from the cable.

Will FST duct sealant degrade over time?

FST is designed to be a long-term sealant. The surface will yellow with exposure to sunlight (UV) which does not affect the sealant’s performance. The surface can be painted to protect the seal from UV exposure. It is resistant to diluted acids and bases, gasoline, oils, and most unsaturated hydrocarbons.

Are foam duct sealants compatible with all cable jacket types?

FST, AFT, and ZipSeal sealants are compatible with common cable jacket materials. The cured foam is an inert solid that does not affect cable components. It does not change the physical or electrical properties of cable, based on tensile elongation and volume resistivity testing.

Have any questions?

Do you have additional questions about foam duct sealants? We’re happy to provide you an answer and update our FAQ for future readers.