Why Are Airtight and Gastight Conduit Seals Important?

This paper explains the importance of sealing ducts or conduits to stop the flow of air and potentially dangerous gasses. It also explains some of the methods to test the air or gastightness of a seal.

Safety should be a primary goal of an effective sealing strategy. For this reason, a sealing strategy should require that electrical and communication ducts be sealed at all building entrances to limit ingress of dangerous gases such as carbon monoxide, methane, and hydrocarbon volatiles. Sealing is sometimes even mandated in areas where methane is present in the underground environment.

Carbon monoxide is a toxic and combustible gas that is generated during the anaerobic decomposition of cable insulation, as well as from other sources. There are instances where high concentrations forced the evacuation of entire buildings. Deadly carbon monoxide has a large flammability range and supports combustion events.

A good conduit sealing protocol improves indoor air quality. Duct seals prevent allergens and other outdoor chemicals and pollutants from entering buildings. These invisible but persistent irritants can make life miserable and over time, cause long-term health issues.

| Related Content: Is Meeting a Standard Enough?—An Examination of Duct Sealing Code Compliance. |

What Does the Code Say?

The National Electric Safety Code (NESC) Section 322.B.4 states:

The portion of conduit installed through an exterior building wall, floor, or roof shall have seals inside the conduit and external seals on the outside surface of the conduit at the point of entry to the building intended to limit the likelihood of the entrance of gas into the building. The use of seals may be supplemented by gas-venting devices in order to minimize building up of positive gas pressures in the conduit.

While many electric codes describe sealing conduits or raceways against moisture, the NESC is specific about sealing out gases for safety reasons. The idea is to keep air and gas from passing from outside the building to inside the building, and from one room to another.

How Much Gas Pressure Must a Seal Hold?

Gases are comprised of small molecules, constantly in motion. These molecules continue to move and bump into each other. Under increased pressure, there are more and more molecules moving in the same space. These molecules exert a repulsive force and push against each other. Gas constantly expands to fill a volume. If allowed, gas will expand to flow through a conduit and into a building. Thus, even a small pressure differential can have a lot of strength. Air is just one gas mixture, but it is the most practical example of this phenomenon. An inflated dome is a good example of this force. The inside air pressure only needs to be slightly higher than the outside pressure, a differential of 0.0036 psi (.00025 bar), to hold the dome in place.

| Related Content: Sealing Conduits for Resilient Electrical and Telecommunication Systems |

The pressure differential between the outside atmosphere and inside the building is minimal. To be effective, the building seal does not have to hold a high pressure differential. To be gastight, the seal simply needs to hold the gas (air) completely, without points of leakage.

differential. To be gastight, the seal simply needs to hold the gas (air) completely, without points of leakage.

How to Know When a Seal is Airtight and Gastight

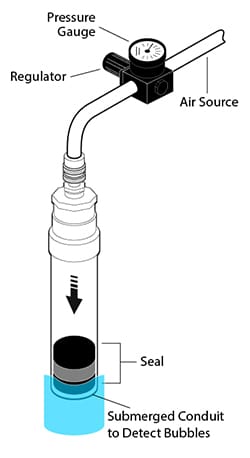

Pneumatic pressure testing is similar to hydrostatic testing and is a good way to test for a robust gas seal. Hydrostatic testing is done to test against high levels of water head pressure that can occur in underground systems. The setup for pneumatic testing is the same except the water is eliminated. Air (or other gas) pressure is exerted directly against the seal.

In this system, a duct seal is completed, and gas pressure is added and measured using a control gauge. Gas leakage can be detected through pressure loss on the pressurized side of the seal, or by detecting gas flow using a manometer through the other end of the seal. It is possible to detect gas flow with a balloon or the presence of gas bubbles with the system immersed underwater.

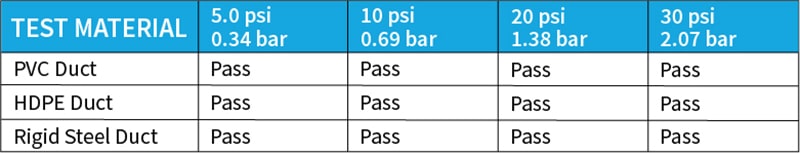

Well-designed duct seals can hold a considerable amount of pressure. Below are various test results.

Closed-Cell Polymer Seal

Well-designed duct seals can hold a considerable amount of pressure. Below are various test results.

Mechanical Seal

The test results show that these are strong seals that hold high pressures. Automobile tire pressure is commonly 32 to 35 psi, and these specialty duct seals can hold a similar force. This is much higher than is typically necessary to create an airtight conduit seal for code purposes.

Air Flow vs. Air Pressure

Sometimes the goal is to minimize the passage of gas but allow for some gas venting. In this case, it is desirable to understand the gas flow through the seal.

Air pressure is the measure of force applied to an area. In the pneumatic seal tests, the seal is subjected to gas pressure measured in force per area: psi (pounds per square inch) or bar (106 dynes per square centimeter). If it is necessary to vent the seal, the measurement of gas flow becomes interesting. Flow is the measure of gas volume over time. Flow is measured in scfm (standard cubic feet per minute) or m3/min (cubic meters per minute).

| Related Content: Understanding and Mitigating Manhole Explosions: An Interview with Stuart Hanebuth |

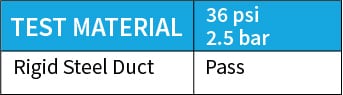

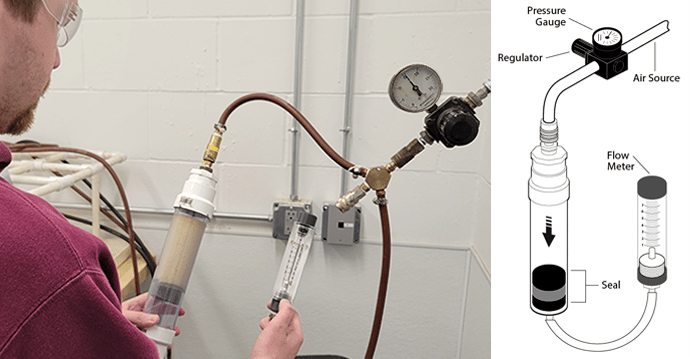

Air Flow Restriction and Measurement

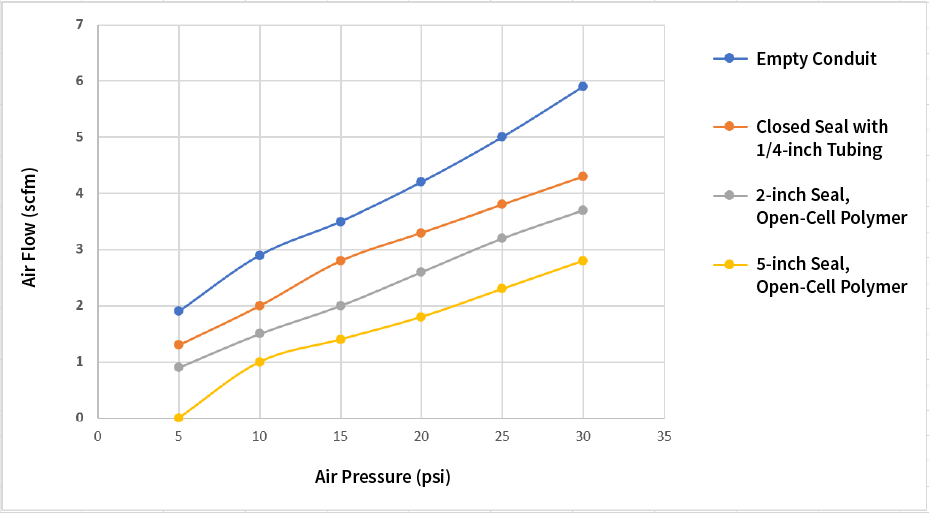

If the seal requires a gas venting function, it is possible to measure changes in air flow rate. A test apparatus was developed using a source of compressed air with adjustable pressure leading to a duct seal on one end. A flow meter is connected to the other side of the duct to measure standard rate of flow.

The incoming air pressure can be varied from 5 to 30 psi (.3 to 2 bar) in 5 psi (.34 bar) increments, and the resulting airflow is recorded.

In this testing, an empty section of 2-inch (50 mm) conduit was used to record a baseline flowrate. All tests were completed in the same size, 2-inch (50 mm) conduit. An airtight seal was installed with a ¼-inch (6.4 mm) tube to restrict the airflow but still allow for some venting.

In addition, open-cell foams were tested. The cell structure in this polymer allows for some gas and water to pass under pressure. These types of foams are sometimes used to restrict or filter water or air particles. Two different depths of open-cell foam seals were installed into the conduit. The data can be seen in Graph 1.

Graph 1: Air Flow Versus Air Pressure for Various Restrict Seals

Under higher pressure, there is higher flow. It is possible to further restrict flow by reducing the diameter of the tube within the closed seal. It is also possible to use special, open-cell polymer technologies to restrict air flow. Here the flow can be restricted both by the design of the material as well as the depth of the seal.

| Related Content: Why Does Duct Putty Fail to Seal Conduits? |

The Science of Sealing

Solutions exist to seal out gases and hold against high pressures. It is also possible to design flow elements into the seal. Determine your requirements. What are the safety issues? What types of gases are present? How much pressure should be resisted? Once you decide to install a seal, be sure you are using the appropriate sealing solution. Consider the design and review the test results.