Testing How Polywater® UPR™ Restores Structural Integrity to Damaged Utility Poles

A Polywater lab study shows how UPR™ restores structural strength in wooden utility poles, improving compressive performance and preventing decay.

Evaluating Strength Loss in Wooden Utility Poles

Wooden utility poles are essential components of overhead electrical and communication distribution systems. However, they face ongoing threats from biological decay, weathering, and wildlife damage. Even small cavities, such as woodpecker holes, can significantly reduce structural capacity and create a nucleation point for accelerated decay and rot.

Polywater® UPR™ Wood Utility Pole Repair was developed to fill, seal, and protect damaged pole sections, thereby extending service life by halting decay and repelling moisture. These two attributes remain the primary mechanisms by which UPR extends the service life of wooden poles.

Recently, a customer contacted Polywater to ask whether UPR restores the physical strength of utility poles. Although UPR is described as a solution that restores the integrity of damaged utility poles—due to its ability to adhere to and integrate with wood fibers, hardening to a strength comparable to wood—Polywater has not previously claimed that UPR restores mechanical strength. Instead, Polywater has focused on providing customers with concrete data related to product performance. Because the physics of utility pole failure are complex, the company prioritized verifying the primary benefits of UPR rather than speculating on structural restoration.

However, the question of whether UPR could also restore strength remained important to the customer. Consequently, Polywater sought to develop a method to quantify the restorative strength of a utility pole sealed with UPR. As part of this effort, Polywater consulted with a professor of wood products who has extensive experience testing the structural failure of utility poles.

Through several discussions, this expert directed Polywater to ASTM D1036: Standard Test Methods of Static Tests of Wood Poles, which provides standardized procedures for evaluating pole strength. Because destructive testing of full-size utility poles is time- and resource-intensive, the team adopted provisions in ASTM D143: Standard Test Methods for Small Clear Specimens of Timber, which allow for testing smaller samples to determine static bending strength.

| Related Video: Utility Pole Repair Solution |

Developing a Testing Framework to Assess Strength Restoration

The Polywater laboratory selected 1-inch (2.54 cm) diameter southern yellow pine dowels as test specimens, cut to appropriate lengths to approximate utility pole dimensions.

Since wood is an organic and variable material, a large sample size was required for statistical reliability. The lab prepared at least 20 specimens for each of two strength tests—static bending and compression—to minimize variability. Tests compared three conditions:

1. Intact dowels (controls)

2. Dowels with simulated “woodpecker holes”

3. Dowels with holes filled using Polywater UPR-NF

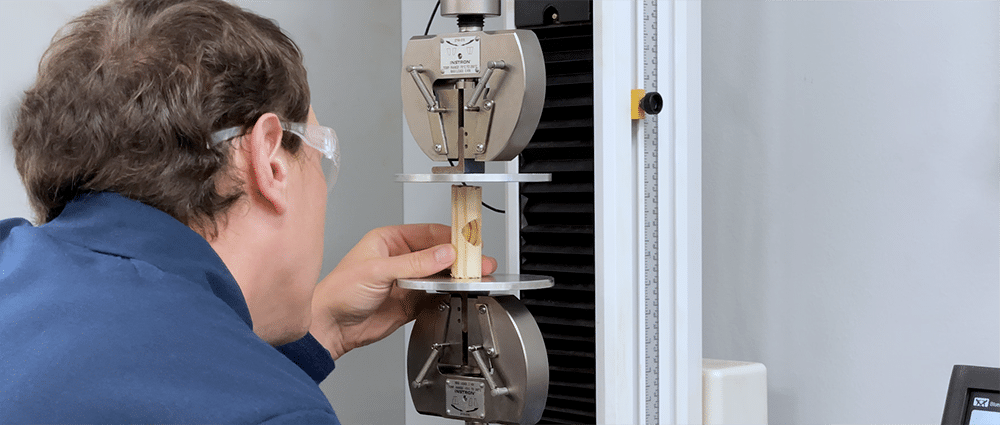

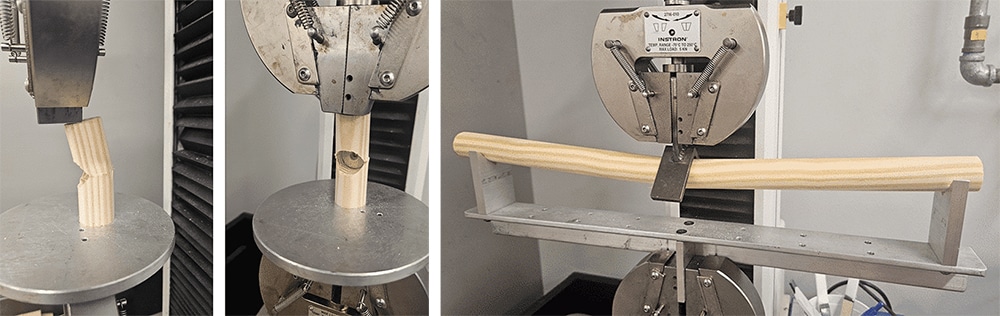

All testing was conducted using an Instron testing machine.

Preparing Dowels to Replicate Real-World Utility Pole Damage

Holes were drilled into the dowel sides to simulate woodpecker damage. A spade bit was centered along both the length and width of each dowel. The hole size was scaled to approximate the relative ratio of a large woodpecker hole in a full-size utility pole. For the compression tests, slightly larger holes were used because the Instron machine approached its load capacity during testing.

For each three-point bend test, the hole face was positioned either upward (toward the crosshead) or downward (facing away from the crosshead) to evaluate directional effects.

Application of Polywater UPR-NF in Controlled Test Environments

Polywater UPR-NF was applied according to the published Instructions for Use, using a 250 ml cartridge. Each prepared dowel specimen thus represented a scaled-down utility pole with a repaired woodpecker cavity.

| Related Content: Polywater® UPR™ Wood Utility Pole Repair Overview Video |

Wood Strength Tests

Static Bending Test

A three-point bend test was performed on the 1-inch (2.5 cm) diameter dowels with a 16-inch (40.6 cm) span between supports. The crosshead was an inverted V-shaped fixture with a width of 1-inch (2.5 cm). All loads were applied perpendicular to the grain at a rate of 0.5 inches (1.3 cm) per minute. A picture of the test is shown above. Maximum load and displacement at maximum load were recorded per ASTM D143. Twenty samples were tested for each configuration to minimize sample variation . Below is a graph showing the results of this testing. The black dots show the maximum and calculated break point for the dowels filled with UPR-NF. Using the maximum force observed for each dowel reduces the standard deviation of the test.

Figure 1: This graph of crosshead displacement vs. force for the UPR-NF filled holes, holes facing up, for the static bend test.

Compression Test

Compression testing was performed on 3-inch/(7.6 cm)-long dowel sections, loaded parallel to the grain at a crosshead speed of 0.5 inches (1.3 cm) per minute. Closed grips were centered on each dowel cross-section, contacting halfway toward the drilled hole, as illustrated in the test setup. Twenty specimens were tested for each condition.

Test Results

The average compression maximum force for the 20 specimens is shown in Chart 1 below.

Chart 1: Compression Results

*The Instron reached its maximum load capacity (1,100 lbs./4.89 kN) in several tests, suggesting that the true average may be higher.

The average maximum force for 20 specimens with and without sealant are shown in Chart 2 below. Results for each orientation are shown.

Chart 2: Static Bending Results

Evaluation of Structural Integrity Improvements Using UPR-NF

The compression test demonstrated a clear increase in strength—over 200% greater than the control samples—and the true value may be even higher, given the test machine’s force limitations. This indicates that UPR increases the compressive strength of wood when filling a cavity.

Under bending loads, strength recovery depended on force direction. When load was applied toward the filled cavity, the repaired specimens showed approximately 20% higher strength than unfilled specimens. Because the side of the pole containing the defect is typically the weakest and most prone to failure, this localized reinforcement represents a meaningful improvement in durability.

| Related Content: UPR-NF Provides Performance at the Extreme |

However, real-world utility poles experience complex, multidirectional forces not easily replicated in laboratory conditions. Therefore, while it cannot be claimed that UPR restores a specific percentage of total pole strength, the study demonstrates that filling cavities with UPR increases resistance to certain loading vectors—enabling poles to better withstand localized stress and deformation.

Beyond mechanical benefits, the primary advantage of Polywater UPR remains its protective function. The material flows to completely fill cavities, expels moisture, and achieves an exothermic reaction that kills microbes and bacteria. These combined effects halt decay and extend service life. Consequently, while UPR provides measurable short-term strength improvement, its long-term value lies in mitigating deterioration and preserving structural integrity over time.

Key Takeaways

• Polywater UPR restores localized strength to damaged wood under both compression and bending loads.

• Moisture removal and microbial protection further extend pole life beyond immediate reinforcement.

• UPR repairs enhance utility pole resilience, reduce replacement frequency, and improve overall grid reliability.