How Does Temperature Affect Cable Coefficient of Friction?

While it is widely accepted that high temperatures increase cable friction, research was limited. Polywater's new research better quantifies the effect of temperature on coefficient of friction.

Variability in Coefficient of Friction

The Coefficient of Friction (COF) between cable and conduit is a critical factor directly influencing cable tension during installation. The value is dependent on the cable jacket and conduit material. Other studies have shown the influence of sidewall force on the COF. It is also influenced by other factors during installation. One common environmental factor is the temperature of the materials. Field experience has shown that at higher temperatures, the coefficient of friction increases, presumably due to changes in the surface dynamics of the cable or conduit.

Temperature Studies

While it is widely accepted that high temperatures increase cable friction, research was limited. New research, summarized below, better quantifies the effect of temperature on COF. This new study measures COF at a large range of temperatures, confirming that high temperatures increase friction and that lubricants minimize this impact.

Friction Table Testing

COF values were measured at a range of temperatures using the friction table method. Polywater® has collected and analyzed thousands of measurements using this test method over many years. Almost all this testing was completed under ambient conditions 65 – 75°F (18 – 24°C). This standard test method was used to produce new data covering a much larger temperature range, -40 – 122°F (-40 – 50°C).

| Related Content: Measuring Friction on Polywater’s Friction Table |

For this research, conduits and cables were cooled in dry ice prior to testing to simulate cold surfaces. Friction testing continued as cables warmed to ambient conditions, and surface temperature was recorded at the start of each test using an infrared thermometer. To simulate warm temperatures, conduits and cables were conditioned in a 122°F (50°C) oven for one hour prior to testing. All testing was completed using a standard normal force of 200 lbf/ft (298 Kgf/m).

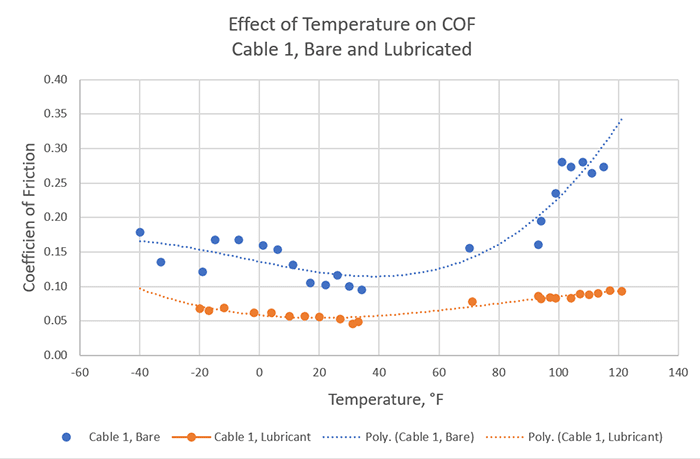

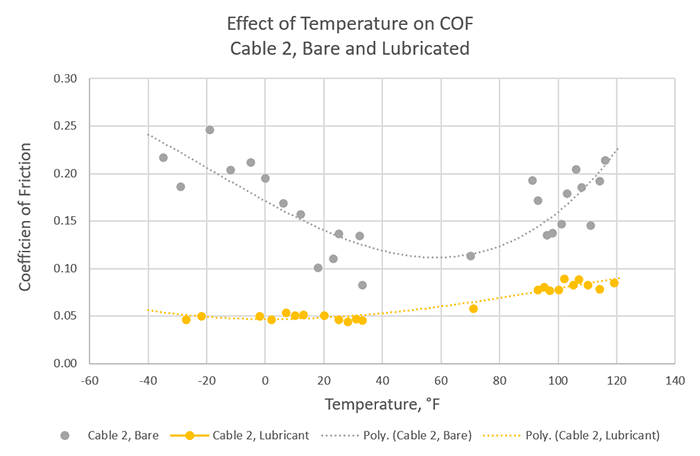

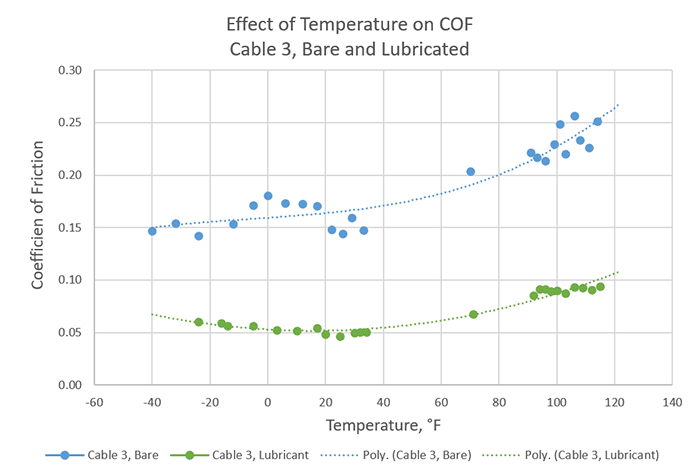

Graphs 1-3 below show the results of this testing across three different cable types. There are some variations between cable types, but for each series, the COF increases at approximately 100°F (38°C) . In some cases, friction also increases at very low temperatures. Lubricant lowers the overall COF as expected. More importantly, the COF increase with higher temperature for lubricated cables is only minimal. Lubricant substantially minimizes the now-documented impact of external variations in temperature.

Graphs 1-3 show the impact of temperature variation on COF. While this increase is dramatic for unlubricated cables, it is minimal once lubricated.

Heat Generation from Friction

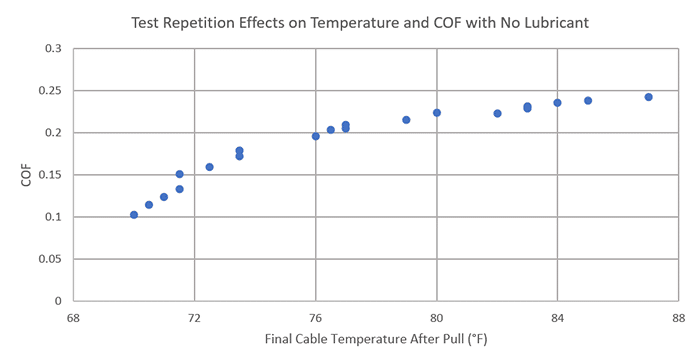

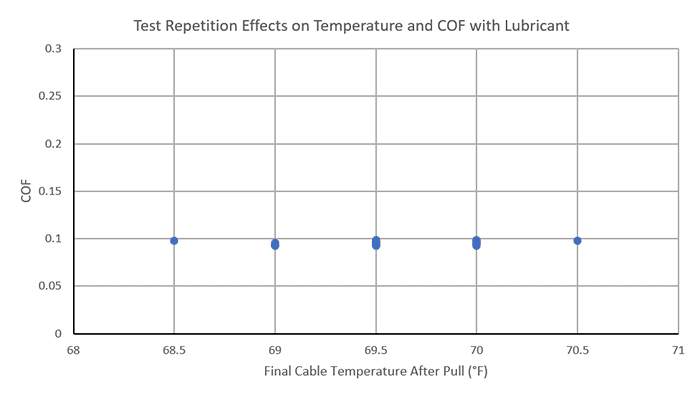

In the next temperature study, there was no deliberate change to the ambient temperature. A reel test was performed to measure temperature increase from friction forces. Cable was pulled at a rate of 60 ft/min (18.3 m/min) through 420° of conduit wrap. Cable was pulled with and without lubricant for 20 repetitions each to simulate longer cable pulls. At the end of each pull, the surface temperature of the cable was measured and recorded using an IR thermometer.

| Related Content: Measuring Cable Pulling Friction with a Reel Test |

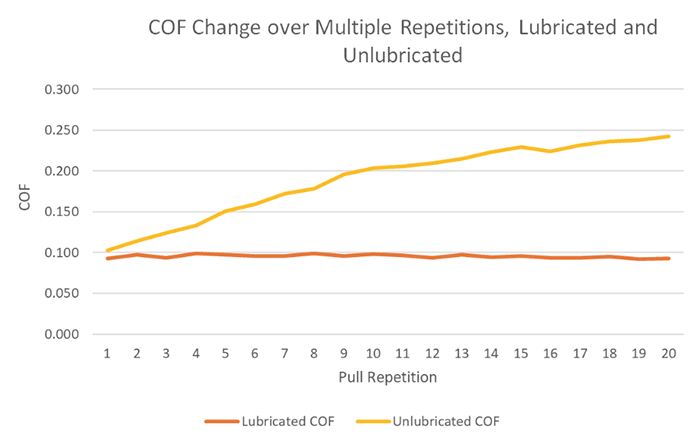

For the cable pulled without lubricant, temperature increased a half degree Fahrenheit after each pull test. From start to finish, the temperature increased 17°F (9°C). When lubricant was used, the temperature showed almost no change throughout the 20 repetitions. By lowering friction, lubricant also lowers the heat effect from frictional forces. Lubricants can also act to absorb and dissipate heat. See Graphs 4 and 5 below.

Graph 4: Temperature increases with each pull repetition for unlubricated cable.

Graph 5: Temperature remains flat with each pull repetition for lubricated cable.

Thus, even when pulling at ambient temperatures, surface temperature can become elevated from frictional forces. Lubricants minimize this heat generation. From the previous work, we know that increased temperature increases COF. The results of the repetition test show this as well. For the non-lubricated pulls, the COF increases with each iteration. For the lubricated pulls, the COF stays steady. See Graph 6. The fact that lubricants reduce heat generation is an additional benefit of cable lubrication.

| Related Content: FAQ – Cable Pulling, Lubrication, and Tension |

Graph 6: Lubricant keeps COF the same over multiple repetitions while the COF with unlubricated cable increases for each repetition.

Lubricant Lowers the Coefficient of Friction Variability

Cable lubricants lower the COF and consequently allow longer cable installation distances whether the cable is pulled or blown. Lubricants minimize heat generation as well. Another benefit, seen here, is that the COF variability from temperature fluctuation is reduced. It is not always possible to control the environmental and temperature conditions where cables are installed. It is possible to specify and use cable lubricant. Cable lubricants produce increased performance predictability.