Coefficient of Friction (COF) Explained

Coefficient of friction explained: Discover answers to commonly asked questions

What is Coefficient of Friction or COF?

Coefficient of Friction (COF) is surface resistance to movement. It is a measure of how sticky or slippery two surfaces are when rubbed together. COF is used to predict force or tension on cable.

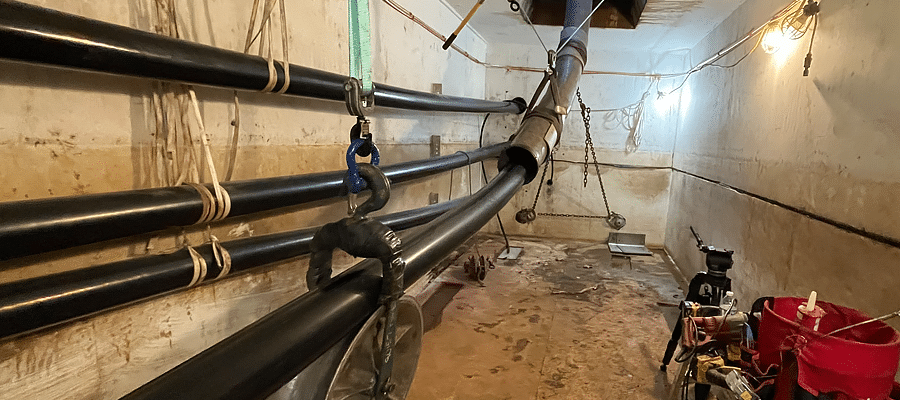

When pulling wire or cable through a conduit, COF directly influences the pulling force applied to the cable to overcome the frictional resistance between the cable and conduit surfaces.

COF formula: μ = F/N

Where:

µ = Coefficient of Friction

F = Pulling (horizontal) force

N = Normal or sidewall force

What is Static COF (µs)?

Static Coefficient of Friction represents the force required to initiate relative motion between two surfaces that are in contact with each other, but not moving. It describes the force required to put a body in motion.

Static COF can be measured using an inclined plane method. µS is derived using the angle at which the object starts to move as well as the gravitational weight of the object.

What is Kinetic COF(µk)?

Kinetic Coefficient of Friction or Kinetic COF represents the resistance to movement once the object or surfaces are in motion.

Kinetic COF is lower than static COF. It is better to keep an object in motion to conserve the additional force required to start moving it. In best practice cable installation, do not stop the pull. Keep the cable moving until it reaches the end of the duct.

How do you calculate Coefficient of Friction, or COF, for cable pulling?

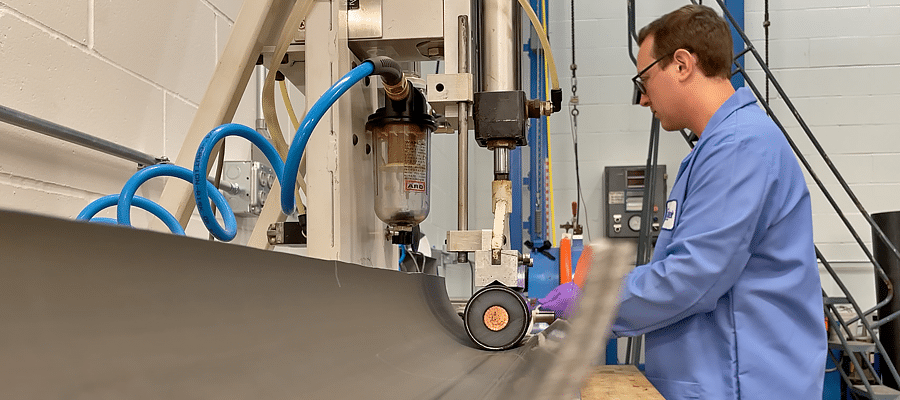

There are several ways to measure the cable forces to calculate Coefficient of Friction, or COF, based on the pull’s geometry. Polywater uses a variety of test methods to study COF between cable and conduit. We have created a very specific testing device, The Polywater Friction Table, to measure the friction between different lubricant, cable, and conduit material combinations. The data collected includes multiple manufacturers/suppliers for each material type. These data have been compiled over years of testing.

Engineers can access this database using the Polywater® Pull-Planner™ software. This tool offers the capability to predict cable tension based on different cable, conduit, and lubricant combinations. The software guides the planning process for the cable installation.

| Learn more about how data from Polywater helps predict COF in a cable pull |

What factors determine Coefficient of Friction, or COF, in a cable installation?

While materials like the cable jacket, conduit material, and lubricant type drive the laboratory Coefficient of Friction (COF) measurement, field conditions further influence this performance during cable installation. The factors that determine Coefficient of Friction, or COF, values are:

- Movement – The energy to initiate motion (static COF) is higher than that required to keep the object moving (kinetic COF).

- Normal Force — Higher pressure will change the surface properties as well. In cable pulling science this is seen as lower COF in bends, under high sidewall force.

- Material Condition – This can include surface oxidation, smoothness of surface finish, cleanliness, etc.

- Temperature – Extreme temperatures will increase COF.

- Lubricant Application – Lubricants respond to surfaces differently. The lubricant must fully coat the two surfaces for optimum performance. Some surfaces are more difficult to lubricate than others.

In the context of cable or wire pulling, the calculation of a meaningful or effective COF considers these factors, as well as knowledge of the materials involved. In other words, the effective COF builds a safety factor into the tension prediction.

| For more information on measuring COF in cable pulling, visit our page on the most frequently asked questions regarding cable pulling, lubrication, and tension |

Why is Coefficient of Friction, or COF, important in cable pulling, cable hauling, or wire pulling?

During an installation, cable or wire is subjected to both pulling tension and sidewall force. These forces should not exceed the limits set by the manufacturer. If these limits are exceeded, the damage to the cable may not be immediately visible. The longevity of the cable can be impacted, lowering its design life by years.

Reducing Coefficient of Friction (COF) is important in cable pulling, cable hauling, or wire pulling because it lowers tension. This is important for several reasons as it allows you to prevent damage to the cable and other assets, keep the installation safe for workers and equipment, make the installation as efficient as possible, and potentially install greater lengths of cable to minimize the number of splices, junction boxes, and vaults.

| For more information on understanding COF in cable pulling, read our article on Coefficient of Friction in Cable Pulling |

How do you reduce Coefficient of Friction, or COF, in cable pulling, cable hauling, or wire pulling?

Engineered cable lubricants play a critical role in reducing Coefficient of Friction (COF) in cable or wire pulling operations. The cable and conduit materials, the condition of the conduit’s interior surface, and the system design all have an impact on COF. Proper planning and installation practices can help ensure the success and safety of cable pulling operations.

| If you would like to know more about proper planning practices to reduce COF in cable installation, learn about the Polywater® Pull-Planner™ software |