Sealing the Divide in Cable Jacket Repair

Polywater® CJR offers a new way to permanently restore damaged fiber optic cable jackets.

Compromised fiber jackets permit water ingress, causing outages.

Fiber optic cable jackets can suffer cuts, scrapes, or lacerations during installation, initial testing or from storms, vegetation, or rodents. These breaches allow water ingress, which may lead to service interruptions—especially in colder climates where moisture can freeze and damage the cable. Common repair methods like vinyl electrical tape or heat shrink aren’t permanent and often fail over time. More extensive repairs, such as splicing or replacing sections, are costly and disruptive to both network owners and their customers. To minimize outages and lower maintenance costs, Polywater was asked to develop a fast, effective, and reliable solution for restoring damaged cable jackets.

Restoring damaged cable jackets with Polywater CJR

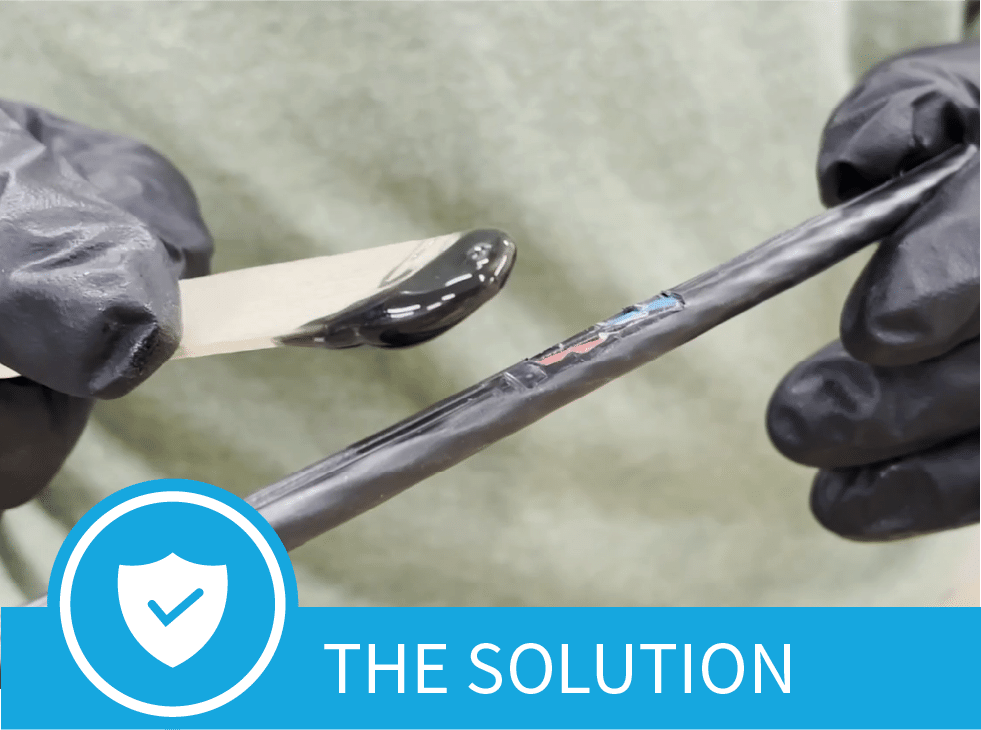

Polywater CJR Cable Jacket Repair offers a fast, effective solution for repairing both underground and aerial fiber optic cable jackets. It’s formulated to bond with all common communication cable materials, sealing cuts and abrasions with a flexible, waterproof barrier. Once cured, it resists peeling or cracking—even with cable movement. CJR is packaged in a convenient, multi-use syringe that requires no special tools and can be applied in seconds. Its ease of use and durable performance make it an ideal solution for service crews and network owners aiming to maintain system integrity with minimal downtime.

A Cost-Efficient, Proactive Solution

Field use of Polywater CJR has exceeded expectations. Its compact, multi-use packaging allows crews to make quick, on-the-spot repairs. Now, crews can keep CJR stocked as a standard part of their maintenance toolkit. While it’s not a replacement for severely damaged cables, CJR helps prevent minor jacket damage from escalating into major outages. Within routine inspections, crews can address multiple cuts in minutes. This proactive approach saves time and reduces costs associated with emergency service calls, truck rolls, and cable replacement—while improving overall network reliability and customer satisfaction.

“Repairing damage to our cable jackets used to require replacing the cable entirely or installing costly enclosures to circumvent any water intrusion. With the new Polywater CJR we can easily repair this damage— quickly and at a much lower cost—and get back to running our network. “ — Sal DiFranco, OSP Engineer