The Push and Pull of Utility Undergrounding

Electrical utility companies are incorporating unique conduit and cable installation methods to help them meet undergrounding goals.

At some point, every generation finds itself saying, “We are living in interesting times.” For many municipal and investor-owned utility companies, this is likely a common sentiment. Ongoing electrical upgrades and expansion projects required to meet increasing energy demand, coupled with the integration of distributed energy resources, have put the world’s energy grid in a perpetual state of “work-in-progress” as it strives to become the grid of the future.

Against this backdrop, utility companies are under increasing pressure. They are not only pursuing decarbonization goals but also implementing system hardening efforts to create more resilient and reliable networks in response to climate change. These efforts aim to reduce unplanned outages, maintain profitability and satisfy customers.

This context has sparked many conversations in our dynamic electric utility industry. One growing conversation is about the conversion from overhead (aerial) to underground power distribution, commonly referred to as “undergrounding,” as a solution to address areas prone to weather-related or vegetation-related outages.

Shifting Perceptions of Undergrounding

Despite being historically associated with high capital costs and complex policymaking, some utility companies are now embracing underground conversion strategies in favor of their long-term benefits and overall cost savings over the electrical asset’s lifespan.

“When you look at the costs associated with events like hurricanes and wildfires on the grid, undergrounding, as a strategy, has some real proven value,” states Mike Beehler, a 40-plus-year veteran of the electrical T&D industry and the national spokesperson for PDI2. In addition to being a proponent of undergrounding, Beehler has publicly called for a discussion on this topic with his paper, 50% Underground by 2040. Beehler adds, “There’s a smart way to approach undergrounding. Innovative tools and methodologies are available, that exist today, that help make it as economic and efficient as possible.”

While there is no silver bullet to help solve the underground conversion challenge, everything from alternative planning and construction tools to unique installation methodologies and techniques are being sought out and vetted by planning engineers and utility companies.

| Related Content: Total Cost of Ownership: Tools for Your Future |

Innovations in Conduit and Cable Installation

An area of interest lies in how to install underground cable into conduits in remote or rugged terrain. The challenging soil conditions in such environments often render traditional excavation and trenching construction techniques ineffective. This challenge becomes especially pronounced in long-distance cable installations for solar and wind farm projects, typically situated in remote terrains, significantly impacting project timelines and costs. Given the increasing investments in renewable energy sources, addressing these challenges has become crucial for enhancing project efficiency.

Conduit Plowing

Before the cable is installed, a continuous line of HDPE conduit is buried using a specialized construction technique. Conduit is fed from a reel while a unique plow system creates a trough for it and lays it in place. This avoids creating a large trench or channel for the installation. The technique is well suited for new road construction projects where the conduit can be installed under the roadway. The plowing system can also be used alongside railroad lines and roadways without creating a major disruption, minimizing transportation interruptions, and thus reducing potential construction costs. Utilizing this installation approach can prove to be more economical than traditional trenching and conduit laying practices.

The Push and Pull Method

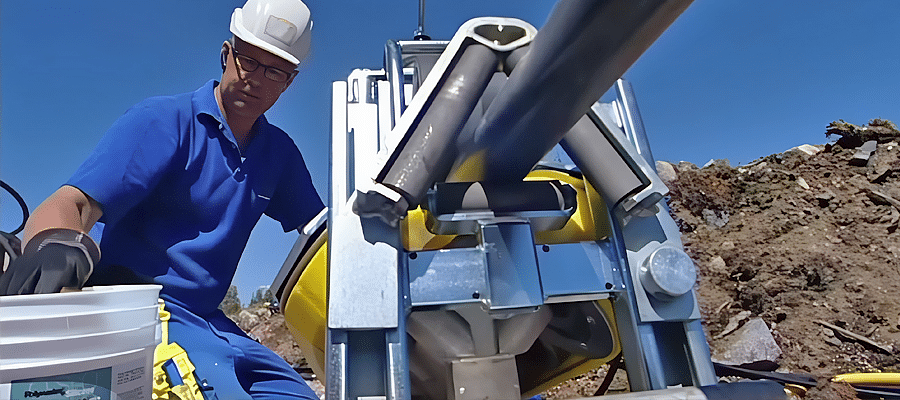

An alternative approach to underground cable-in-conduit installation is the push and pull method. Once the conduit run is in place, the cable can be installed using push and pull methodology. The technique is exactly like its name. On one end, the cable is propelled or pushed through the conduit using specialized equipment, while on the other end, the cable is pulled with an appropriately geared and powered winch. There are several advantages that make it an appealing option. First, this method lowers cable tension, as it balances the forces placed on the cable. Second, it allows for longer cable installation lengths at a speed that is on par with standard cable pulling (between 16 and 20 meters per minute). Due to the longer distance cable run, the number of junction boxes or utility vaults can be reduced in a system design, to minimize project costs. Lastly, the equipment is small and lightweight to facilitate operation and maneuverability in remote or restricted areas.

Conduit Preparation

Some preparation work is needed before cable installation. Due to the nature of the construction environment, the conduit must first be cleaned of any dirt and debris and proved using a mandrel. This minimizes any potential damage to the cable during installation. Then, a pre-lubrication phase is implemented using a lubricating ball equipped with sonar tracking. This process primes the conduit for installing the cable smoothly and allows installers to identify potential damage or constriction of the conduit using the sonar tracker.

| Related Content: FAQ – Cable Pulling, Lubrication, and Tension |

Cable Lubrication and its Benefits

After preparing the conduit line, the cable is ready for installation. An engineered, high-performance cable lubricant is applied to the cable as it enters the conduit. Lubrication is a key component in reducing friction forces between the cable and conduit that contribute to pulling tension and sidewall pressure. The reduction of friction forces not only ensures safe handling of the cable during installation, it also minimizes the power needed to install the cable and the forces on equipment that add to wear and tear.

There are many factors that influence proper lubricant selection for a cable installation project, here are some considerations.

Realizing Undergrounding Project Goals

Utility companies are navigating complex challenges in these “interesting times” as they work to improve the reliability and resilience of the energy grid. Undergrounding, supported by innovative installation methods like the push and pull technique, is emerging as a promising solution to address these challenges.

“Utility companies that are considering undergrounding, need to look at the key areas (in the U.S.) that have already implemented underground conversion strategies and are experiencing the benefits,” says Beehler. “The data is very favorable.”

Areas in the U.S. such as Anaheim, California, and Fort Collins, Colorado began their underground programs decades ago and are mostly underground today. Both have experienced a significant reduction in electrical outages because of undergrounding efforts and have improved reliability and increased customer satisfaction*.

These success stories, supported by compelling data and innovative installation methodologies, are bolstering the argument for undergrounding amongst some utilities. Others, like several large investor-owned utilities, are already on the path toward realizing their undergrounding strategies. For both groups, the key is to implement undergrounding tactics that are more efficient, reliable and economical than past practices. With continued investment in such installation technologies and methodologies, companies can stay on track with their undergrounding project goals and build a resilient and sustainable energy future.

Have any questions?

* 50% Underground by 2040, Michael E. Beehler, MBA, LLC, 2022