Five Most Cited Advantages of Duct Installed Power Cable

Discover the top five advantages of installing power cables in duct systems—improving reliability, safety, efficiency, and long-term performance.

Many power cables around the world are being installed to meet the ever-increasing demand for electricity. A large proportion of these cables are being installed underground because the cable is more protected, repair operations are smoother, and underground installations are more aesthetically and environmentally appropriate when compared to overhead cables. As many power utilities transition from overhead to underground installations, they must decide on the best installation approach to optimize performance of the power grid.

There are three cable installation practices commonly employed to realize the advantages of underground installations: Direct Bury cable in trench, Duct/Conduit laying in trench then installation of cable, and Horizontal Directional Drilling (HDD) installation of duct then installation of cable. The latter two approaches use duct/conduit which offer additional advantages over direct buried cable. Five of the most cited advantages of duct installed cables will be described below.

1. Lower lifetime maintenance/operating costs

2. Extended service life and reusability

3. Better cable installation coordination and flexibility

4. Heat dynamics of duct installed cable

5. Environmental and personnel safety

Lower Maintenance and Operating Costs

Conduit systems significantly reduce the time and cost associated with repairing underground power cables. Unlike direct-buried installations, no excavation is required to access cable faults. The damaged cable can simply be disconnected, pulled from the duct, and replaced. This reduces the time needed to locate the fault and eliminates the need to excavate the trench, remove the damaged section, and then install a cable section to join the exposed cable ends using two splices —as would be needed in a direct buried cable installation.

| Related Content: The Push and Pull of Utility Undergrounding |

A benefit of having fewer splices in the cable can also mean greater reliability. Splices are well recognized as weak points in medium- and high-voltage systems. They are expensive to install, require specialized kits, and are sensitive to workmanship quality. Each additional splice not only increases system cost but also reduces long-term grid reliability. By minimizing splicing requirements, duct systems directly improve system performance while lowering maintenance and operating costs.

The benefits of easier fault access and faster restoration of the power circuit are reflected in industry-standard reliability indices:

• SAIDI (System Average Interruption Duration Index): Average outage duration per customer per year.

• SAIFI (System Average Interruption Frequency Index): Average number of outages per customer per year.

• CAIDI (Customer Average Interruption Duration Index): Average time to restore service after an outage.

Utilities consistently see improved performance on these indices with conduit-installed cables compared to direct-buried installations, translating into higher service quality and lower system costs.

Extended Service Life and Reusability

Duct systems provide long-term infrastructure that can be reused for multiple cable lifecycles. While the average service life of medium- and high-voltage power cable is approximately 50 years, properly installed ducts can last a century or more. This means that when cables reach end-of-life, they can be replaced without the cost, disruption, or permitting effort of installing new ducts.

Reusability of ducts also streamlines upgrades, allowing utilities to deploy higher-capacity cables or newer technologies without duplicating civil construction. This reduces both capital expenditure and project lead time.

| Related Content: Evaluating a Historic Conduit for Upgrade |

Another advantage is the ability to remove and recycle retired cables. Direct-buried cables are often abandoned in place due to the high cost of excavation. In contrast, cables installed in duct can be easily pulled out, creating opportunities for material recovery and recycling that partially offset replacement costs.

Better Cable Installation Coordination and Flexibility

The use of underground conduits significantly enhances the flexibility and coordination of power cable installation projects. This flexibility is particularly valuable in projects where multiple stakeholders, including utilities, civil contractors, and equipment suppliers, must work together to meet tight schedules and budget constraints while minimizing disruption to the public and surrounding infrastructure.

Underground cable installations involve a complex sequence of activities: route design, permitting and Right-of-Way (ROW) negotiations, procurement of cables and accessories, delivery logistics, trenching, duct placement, and ultimately cable installation and termination. Delays in any one of these steps can lead to cost overruns and scheduling conflicts if not effectively managed.

Ducted cable systems provide a strategic advantage in handling these uncertainties. Unlike direct-buried installations, where trenching and cable laying must occur in a tightly coordinated sequence, ducts allow these activities to be decoupled. The trench can be excavated, ducts installed, and the area backfilled well in advance of cable delivery. When the cable arrives on site, it can be quickly pulled through the pre-installed duct without the risks and logistical complications associated with open trenches.

This decoupling of civil works from cable installation gives utilities and contractors greater– scheduling flexibility, improves safety, and reduces exposure to weather-related or logistical delays; ultimately supporting more reliable project delivery.

Better Heat Dynamics of Duct Installed Cables

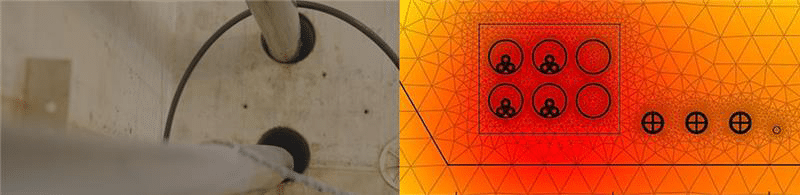

There are persistent misconceptions about I²R (Joule) losses in duct-installed power cables. A common belief is that the conduit wall acts as an insulating barrier, trapping heat inside the duct and thereby reducing cable ampacity. This assumption may skew the design of a cable installation away from the benefits of cables installed in conduit.

In practice, duct systems often enhance heat dissipation compared to cables buried directly in soil. The duct’s larger thermal mass creates an expanded cooling envelope in the surrounding soil. This broader thermal field improves heat transfer to the soil and minimizes the formation of dry zones—areas where soil moisture evaporates, reducing its thermal conductivity. Dry zones are a frequent problem with direct-buried cables and are a primary contributor to localized overheating.

| Related Content: Heat Management in Underground Power Cable Installations |

By mitigating dry zone formation, ducts help maintain efficient thermal conductivity within the duct, as well as in the surrounding soil, preventing excessive heat buildup in the cable and supporting higher ampacity. Today, advanced thermal modeling allows engineers to accurately predict how different installation methods influence heat generation and dissipation. These analyses help identify the optimal configuration for a given project, improving cable reliability, extending asset life, and stabilizing current-carrying capacity under varying operating conditions.

Environmental and Personal Safety

Reduced Environmental Impact

After initial installation of underground ducts, future disruptions to the natural environment can be averted. Unlike direct-buried cable installations, which require extensive excavation for both maintenance and repair operations, ducts allow cables to be replaced or upgraded with minimal soil disturbance. This preserves vegetation, maintains soil structure, and protects local habitats—advantages that are especially important in environmentally sensitive areas.

Not only do ducted systems help reduce the impact of dry zones on a ampacity as discussed above, but they also help to maintain long-term thermal soil properties. By reducing the formation of dry zones—areas where soil moisture evaporates and thermal conductivity declines—ducts support more stable heat dissipation, which helps preserve soil moisture balance and protects nearby plant life from thermal degradation.

Because ducts shield cables from premature aging, they extend asset life and reduce the frequency of repairs and replacements. Fewer repairs or replacements mean less construction activity, less waste generation, and a smaller environmental footprint over the lifecycle of the system.

| Related Content: Protecting Workers in Underground Cable-in-Duct Installations: The Significance of Quality Lubricants |

Enhanced Worker and Public Safety

The conduit itself acts as a protective barrier, isolating energized cables from direct contact with soil and construction activities. This reduces the risk of accidental strikes during excavation, limits exposure to high surface temperatures, and lowers the potential for fire hazards affecting nearby infrastructure and personnel.

From a maintenance perspective, ducted systems allow for safer, faster interventions. Damaged or aging cables can be removed and replaced with minimal excavation, reducing the time crews spend in hazardous conditions. Access through manholes or pull boxes further improves safety compared to direct-buried installations, which require open digging and carry higher risks of accidental damage during repair.

Ducts also improve public safety. In the event of a fault, thermal and electrical effects are largely confined within the duct, preventing direct exposure to the soil or surrounding structures. This containment reduces risks to nearby utilities, buildings, and members of the public.

By combining reduced environmental disruption with improved worker and public safety, ducted installations deliver clear advantages over direct-buried cables. They protect ecosystems, extend cable life, minimize waste, and provide a safer working environment for utility crews—all while enhancing reliability for the customers they serve.

The Many Advantages of Duct Installed Cables

Important operational, safety, and economic advantages are created when power cables are installed in duct instead of being directly buried in the ground. Lower maintenance costs are realized in ducted cable by facilitating the location and repair of cable faults. The reusability of existing duct can reduce the cost and time to upgrade or replace cables. The separation of civil works from cable installation by using ducts gives utilities and contractors greater scheduling flexibility, improved safety, and reduced exposure to weather-related or logistical delays during the cable installation process. In some cases, the installation of power cables in duct can maintain higher ampacity levels through better heat dissipation and creation of a large cooling envelope in the soil. In addition to protecting maintenance crews and the general public, ducts also play an important role in protecting the cable from exposure to detrimental soil characteristics, water, and damage from pests.

The advantages of duct-installed power cables are becoming increasingly evident around the globe. As more utilities transition from overhead to underground systems, the question remains: should cables be buried directly or installed in duct ? Those who choose conduit often invoke the German proverb, “Wer billig kauft, kauft zweimal”—“He who buys cheap, buys twice.” They see conduit systems as a long-term investment in reliability and resilience. Yet, some decision-makers remain skeptical, weighing upfront costs against long-term value. Over time, however, the superior protection, longevity, and performance of ducted systems continue to make a compelling case—one that’s hard to ignore as the power infrastructure of the future takes shape.